Call us today at (800) 728-0818

A monorail crane system is a type of overhead lifting device that runs along a single stationary beam or track. These systems are ideal for moving loads along a fixed path and are commonly used in production lines, assembly operations, and parts transfer applications.

A monorail crane system is a type of overhead lifting device that runs along a single stationary beam or track. These systems are ideal for moving loads along a fixed path and are commonly used in production lines, assembly operations, and parts transfer applications.

Monorail systems move materials and parts in a fixed path along a single rail. An overhead monorail system is an excellent solution when moving parts from station-to-station in an assembly facility, when storing/queueing parts overhead to save floor space, or staging parts in a paint booth or similar area. When using a straight or simple loop monorail path, the system can easily be mounted using a freestanding frame system or directly hung from the existing building structure (if the building design allows).

Complex systems can be hung using the same methods but may take additional structural steel to support the additional track devices i.e., tongue switches, sliding switches & interlocking latches. Using enclosed track or patented track would be best for a complex monorail system. AFE Crane prefers using Acco Louden patented track, due to their vast variety of components for monorail systems. AFE Crane is able to increase safety & productivity by designing a monorail system that suits your needs.

Motorized carriers are used for high capacities and automated motion on overhead monorail systems. Typically, motorized carriers are designed to transport bulky items from sub-assembly lines to the main assembly line. Carriers often use long, complex monorail paths that include many switches and latches. Staging areas and/or latching bridge cranes can also be added to the monorail system for queuing or to create more floor space and speed up assembly tact times. Motorized carriers are custom designed for user’s specification to ensure efficient operation.

Tractor drives are specialized devices designed to push and pull carriers along monorail systems, crane runways & bridges. They can be integrated into existing hand-push trolleys or end trucks to automate hoist or bridge motion. Typically, tractor drives are powered with electricity, but compressed air may also be used.

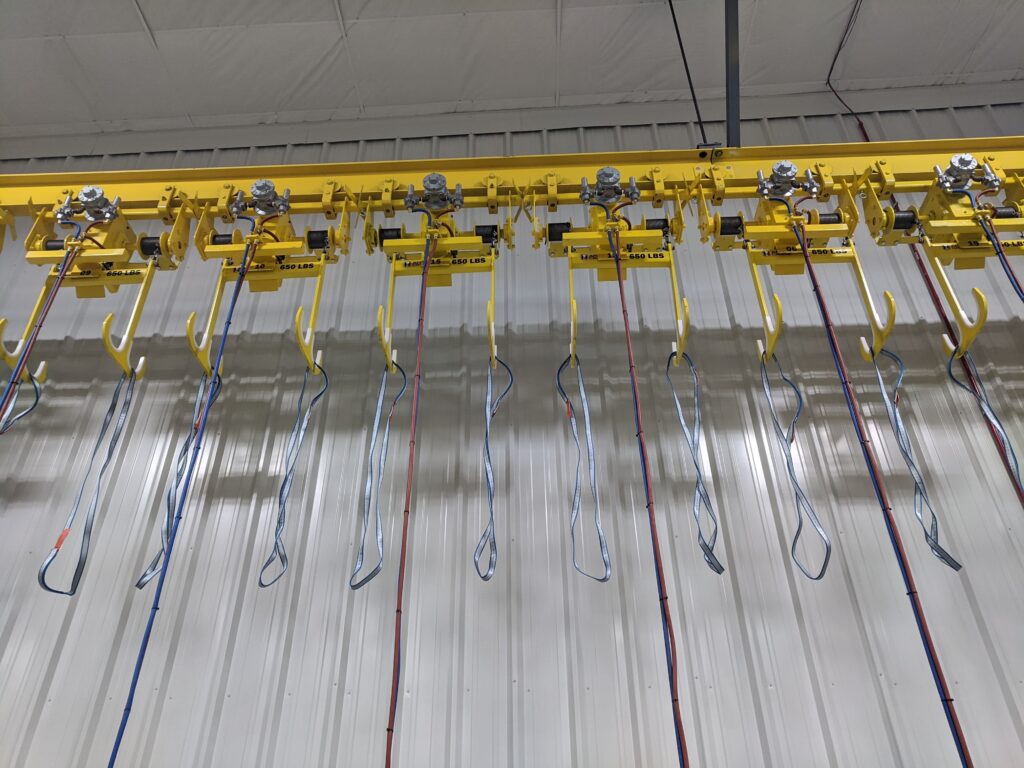

Hand push trolleys are often used to queue material on an overhead monorail system. Push trolleys are typically less than 2 tons and are used in low headroom applications. These trolleys can utilize a powered or hand hoist or a specially designed part hanger. Hand push trolleys are typically used in small parts staging/assembly, blasting lines, paint booths, and many maintenance applications.

Enclosed track systems are generally designed for easy installation. Many manufacturers offer prefabricated sections that can be easily assembled on-site. Maintenance is also simplified due to the reduced need for cleaning the track itself.

Weight of loads: If you need to handle very heavy loads, a Monorail system might not be the most suitable option. Workspace limitations: If headroom is limited, a Monorail system's single track design can be a significant advantage.

Facility layout: Consider the complexity of your workspace and how the crane will navigate it. A Monorail system with curves and switches might be necessary for intricate layouts.

Budget: Monorail systems are generally more cost-effective than overhead cranes, so factor in your budget constraints.

Monorail cranes are an excellent choice for various applications, including:

Assembly lines: They efficiently move materials along production lines due to their ability to integrate with workstations.

Warehouses: Monorails can be used for loading, unloading, and transporting palletized goods within warehouses.

HVAC systems: They can be helpful for installing and maintaining heating, ventilation, and air conditioning equipment.

Machine shops: Monorail systems can be used to move machinery components or tools within a workshop.

Food processing facilities: Stainless steel monorail systems are suitable for clean environments where hygiene is a priority.