Call us today at (800) 728-0818

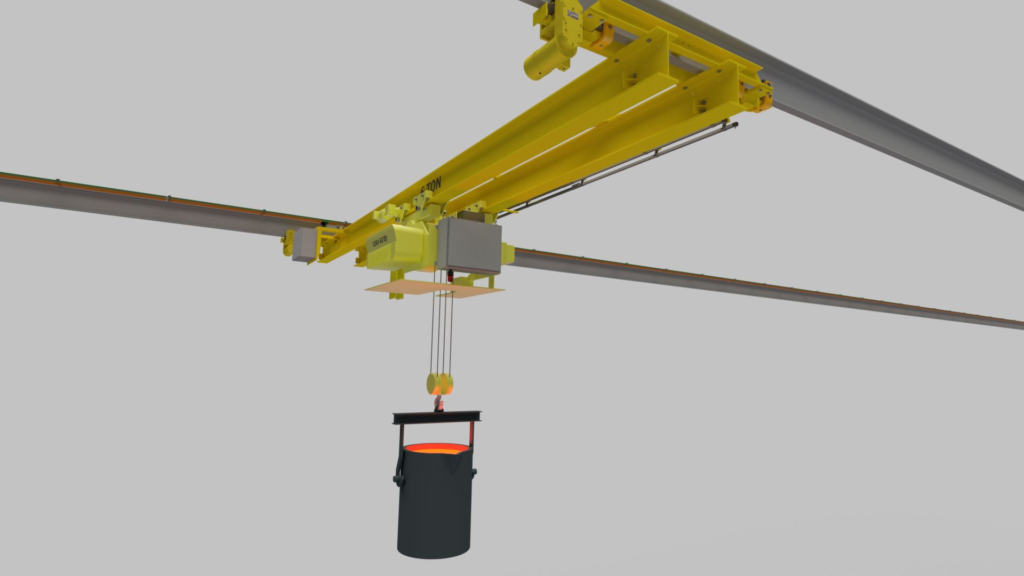

A foundry crane is a specialized overhead crane designed to operate in extreme heat and harsh industrial environments. These cranes are typically used to transport heavy loads such as molten metal, requiring robust construction and enhanced safety features to withstand the demanding conditions.

A foundry crane is a specialized overhead crane designed to operate in extreme heat and harsh industrial environments. These cranes are typically used to transport heavy loads such as molten metal, requiring robust construction and enhanced safety features to withstand the demanding conditions.

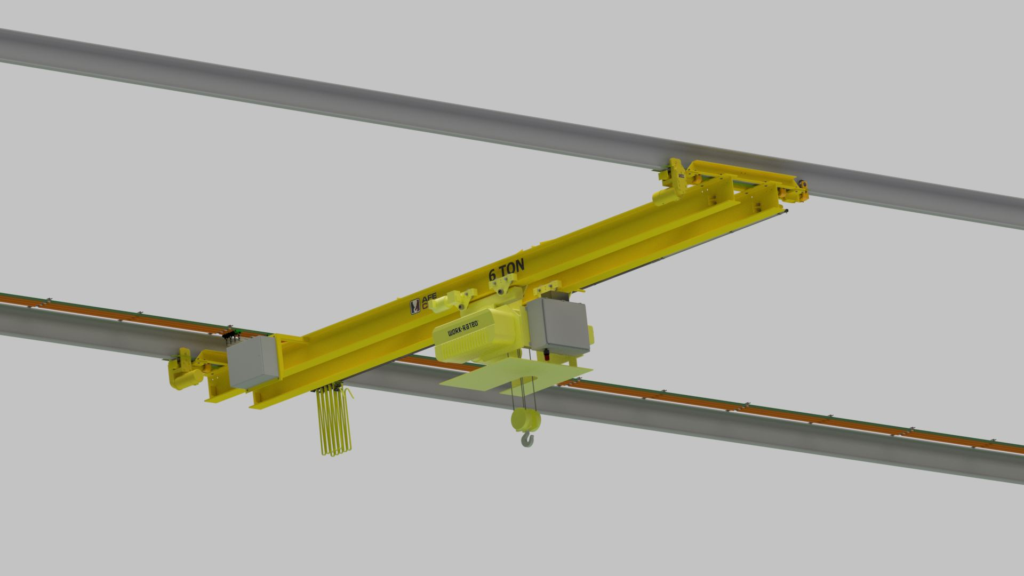

Foundries present unique lifting challenges, from high ambient temperatures to the need for precision handling of hazardous materials. AFE Crane designs and fabricates custom bridge crane systems tailored to meet these extreme conditions. We follow strict industry standards—including ASTM E2349 (2019) and NFPA 70: National Electric Code (2023)—to ensure compliance, reliability, and safety. Each foundry crane is engineered with high-performance components and thermal protection measures to maintain structural integrity and operator safety, even in the most punishing environments.

Foundries present unique lifting challenges, from high ambient temperatures to the need for precision handling of hazardous materials. AFE Crane designs and fabricates custom bridge crane systems tailored to meet these extreme conditions. We follow strict industry standards—including ASTM E2349 (2019) and NFPA 70: National Electric Code (2023)—to ensure compliance, reliability, and safety. Each foundry crane is engineered with high-performance components and thermal protection measures to maintain structural integrity and operator safety, even in the most punishing environments.

Because foundry operations can be dangerous, bridge cranes used in these facilities need to have a number of safety features, such as special overload protection, heat shields, additional drop lugs or safety cables, and warning alarms for added safety during traverse motions.

Foundries deal with molten metal at extremely high temperatures. Bridge cranes in these facilities need to be constructed from heat-resistant materials to withstand the ambient heat without warping or losing strength. Special controls and electrical components may also need to be used to withstand these high temperatures.

Foundries often move large and heavy objects, such as crucibles filled with molten metal, molds, and castings. Bridge cranes designed for foundries need to have a high lifting capacity to handle these heavy loads.

Foundries can be dirty places with dust, smoke, and metal particles in the air. Bridge cranes used in these environments need to be durable and resistant to wear and tear.

Variable speed drives allow the operator to precisely control the movement of the crane, which is important for safe and efficient operation in a foundry.

Hook rotation allows the load to be rotated while it is being lifted or lowered, which can be helpful when pouring molten metal or positioning castings.

Foundry cranes operate in extreme conditions, requiring specialized features to ensure durability, reliability, and safety. To meet the demands of high-temperature environments, AFE Crane offers a range of customization options designed to enhance performance and longevity.

Protects critical crane components, such as electrical panels, from radiant heat exposure, extending equipment life.

Shields the hook block from excessive heat, reducing the risk of heat-related damage to the lifting mechanism.

Provides robust electrical components that meet industry standards for heat resistance and environmental protection.

Ensures that motors and brakes can withstand high operating temperatures without degradation.

Specialized materials designed to perform reliably in extreme heat conditions, preventing premature wear and failure.

If you don’t see the customization you’re looking for, AFE Crane can design a solution to fit your specific needs. Contact us to discuss your requirements.

AFE Crane’s group of industry expert engineers specialize in custom-made foundry cranes and lifting solutions. From designing crane systems for foundries to installation and maintenance AFE Crane has been dedicated to delivering quality efficient and safe crane solutions to the Midwest since 1983.

AFE utilizes a large comprehensive supply chain for materials and parts in addition to establishing long term relationships with our parts vendors. This relationship helps us to expedite parts so that your equipment can be repaired quickly.

This file category has no files to display

This file category has no files to display

Heavy-Duty Cranes Engineered for Hot Metal HandlingAt AFE Crane, we specialize in designing and manufacturing heavy-duty crane systems built to withstand the extreme conditions of

A foundry crane is a specialized overhead crane designed to handle molten metal, slag, and other materials in high-temperature environments. Common applications include pouring molten metal, transporting ladles, and managing heavy loads in foundries and steel mills.

Foundry cranes include heat shields, high-temperature wiring, thermal insulation, and cooling systems to protect components from extreme heat.

Safety features may include anti-sway technology, overload protection, thermal sensors, emergency stop controls, and redundant braking systems.

Yes, we provide repair, maintenance, and replacement services to ensure your foundry crane operates safely and efficiently.