- Overhead Cranes

- Workstation Cranes

- Monorails

- Hoists

Call us today at (800) 728-0818

A workstation crane is a lightweight overhead crane system designed to improve material handling efficiency in smaller or more confined work areas. These systems are modular and typically feature enclosed track bridges and runways to support lifting tasks ranging from 100 pounds to 2 tons.

A workstation crane is a lightweight overhead crane system designed to improve material handling efficiency in smaller or more confined work areas. These systems are modular and typically feature enclosed track bridges and runways to support lifting tasks ranging from 100 pounds to 2 tons.

AFE Crane offers a full range of enclosed track workstation bridge cranes from top manufacturers. These systems are engineered for smooth, manual operation and are ideal for repetitive lifting tasks in assembly lines, manufacturing cells, or maintenance areas. The enclosed track design resists dirt buildup and maintains precise wheel alignment for reduced maintenance and better performance over time. With custom configurations available, AFE Crane can design and install a workstation crane that enhances productivity while fitting seamlessly into your facility layout.

AFE Crane offers a full range of enclosed track workstation bridge cranes from top manufacturers. These systems are engineered for smooth, manual operation and are ideal for repetitive lifting tasks in assembly lines, manufacturing cells, or maintenance areas. The enclosed track design resists dirt buildup and maintains precise wheel alignment for reduced maintenance and better performance over time. With custom configurations available, AFE Crane can design and install a workstation crane that enhances productivity while fitting seamlessly into your facility layout.

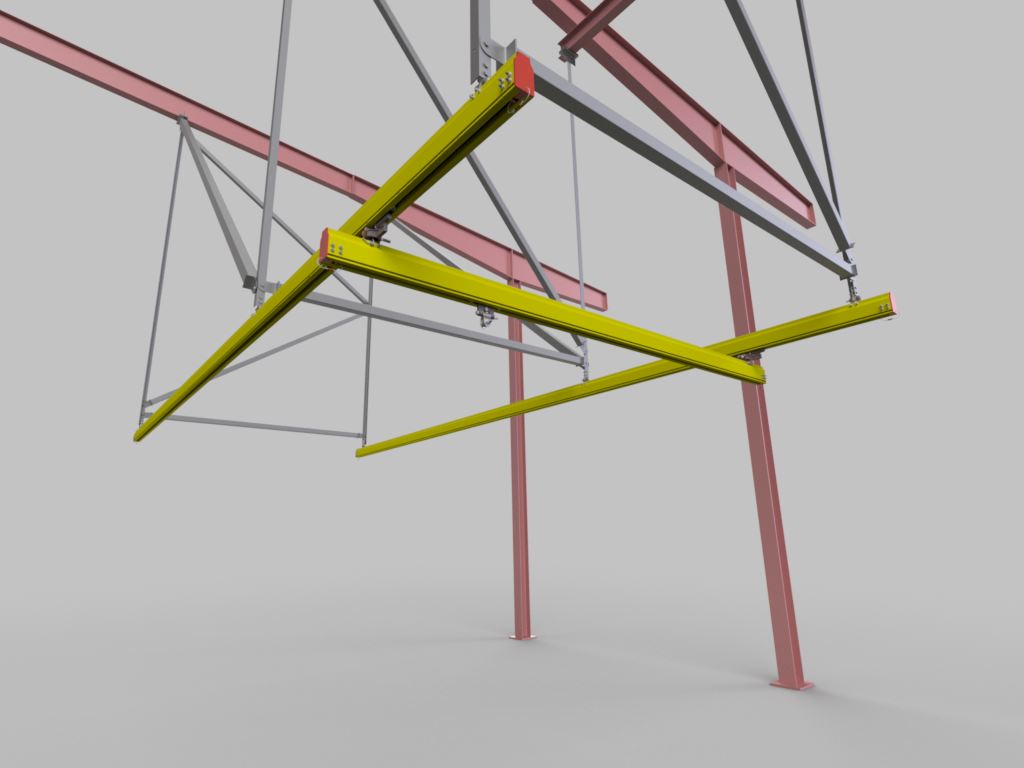

Freestanding crane systems are pre-engineered systems that include columns and header beams to support the runways. A freestanding workstation crane system can be installed without interfering with an existing overhead bridge crane. These crane systems are easy to install and typically do not require concrete footings.

Ceiling mounted bridge cranes include hanger rods (or tubes) which attach to beam clamps to allow the crane system to hang from an overhead structure, such as building trusses. Ceiling mounted systems require additional structural members for sway and trust bracing. Alternatively, these runways can be supported by hangers that hold the runways flush to the underside of building trusses (or similar overhead structure).

Workstation cranes can be tailored to meet specific application needs, ensuring optimal performance and efficiency in a given workspace. A variety of customization options are available to enhance usability, accommodate space constraints, and improve load handling capabilities.

Choose between ceiling-mounted cranes for maximizing floor space or freestanding systems for flexibility in installation without requiring building support.

Ideal for low headroom applications, these trolleys optimize lifting height by keeping the hoist positioned between the bridge girders.

Extendable bridge sections allow for reaching beyond the standard coverage area, improving access to hard-to-reach work zones.

Motorize the bridge or hoist trolley for smooth and precise movement, reducing manual effort and improving productivity.

Options include conductor bars for a streamlined power supply or festooned wiring for a flexible and modular configuration.

Prevents bridges from overloading runway capacity or entering restricted areas by providing controlled stopping points.

Designed for integrating vacuum lifters, these trolleys enable efficient material handling by supporting and guiding vacuum hoses along the bridge.

If you don’t see the customization you’re looking for, AFE Crane can design a solution to fit your specific needs. Contact us to discuss your requirements.

AFE utilizes a large comprehensive supply chain for materials and parts in addition to establishing long term relationships with our parts vendors. This relationship helps us to expedite parts so that your equipment can be repaired quickly.

In any repair shop, efficiency and safety matter. Technicians position motors, handle gearboxes, and move components every day. Lifting equipment should support the task, not

Overview of Weight Overload Protection Weight overload protection is a critical safety feature in overhead crane and hoist systems. These mechanisms prevent equipment from lifting

In modern industrial environments, efficient and safe material handling is crucial for maintaining productivity and ensuring worker safety. The ProPath™ Automated Workstation Crane stands out

At AFE Crane, we are committed to providing industry-leading lifting solutions tailored to your facility’s needs. That’s why we proudly distribute Kundel’s K-Trac Systems, a

As automotive manufacturers push for greater productivity, efficiency, and safety, the use of bridge cranes has become essential to modern production processes. These high-performance lifting

Efficiency and safety are critical in industrial settings. Unified’s ProPath® Automated Workstation Crane is transforming material handling with advanced automation, enhancing productivity and operational safety.

Workstation Cranes are designed for repetitive applications, workstation cranes are commonly found in warehouses, workshops, automotive plants, assembly lines, and distribution centers. Being lightweight and ergonomic with enclosed tracks, makes them easy to install in indoor facilities.

Key factors include load capacity, track length, mounting options, available workspace, and the type of lifting tasks being performed.

Yes, workstation cranes can be motorized using tractor drives for both the bridge crane and the hoist trolley. This allows for smoother, more efficient movement of loads and reduces manual effort, making it ideal for applications requiring frequent or heavy lifting.