Call us today at (800) 728-0818

A crane runway is the support system for an overhead crane providing both vertical and horizontal stability for the crane as it moves, allowing the crane to move smoothly and safely across its designated area. The structure is typically made up of structural steel beams, columns, and rails. Columns provide vertical support for the beams, anchoring the entire runway system. Rails mounted on top of the beams serve as the running surface for the crane’s wheels.

A crane runway is the support system for an overhead crane providing both vertical and horizontal stability for the crane as it moves, allowing the crane to move smoothly and safely across its designated area. The structure is typically made up of structural steel beams, columns, and rails. Columns provide vertical support for the beams, anchoring the entire runway system. Rails mounted on top of the beams serve as the running surface for the crane’s wheels.

Top running crane runway systems are used for top running single girder cranes along with top running double girder cranes. Additionally, some specialty crane systems are also designed to utilize a top running runway system.

Generally, this runway style typically uses ASCE Rail or square bar that is affixed to the top of a structural beam as a running surface for the top running crane. There are multiple support options for top running crane runway systems. Being supported from a haunch (which is attached to a side of a building column) or utilizing a freestanding structure are the most common ways of supporting a top running crane runway.

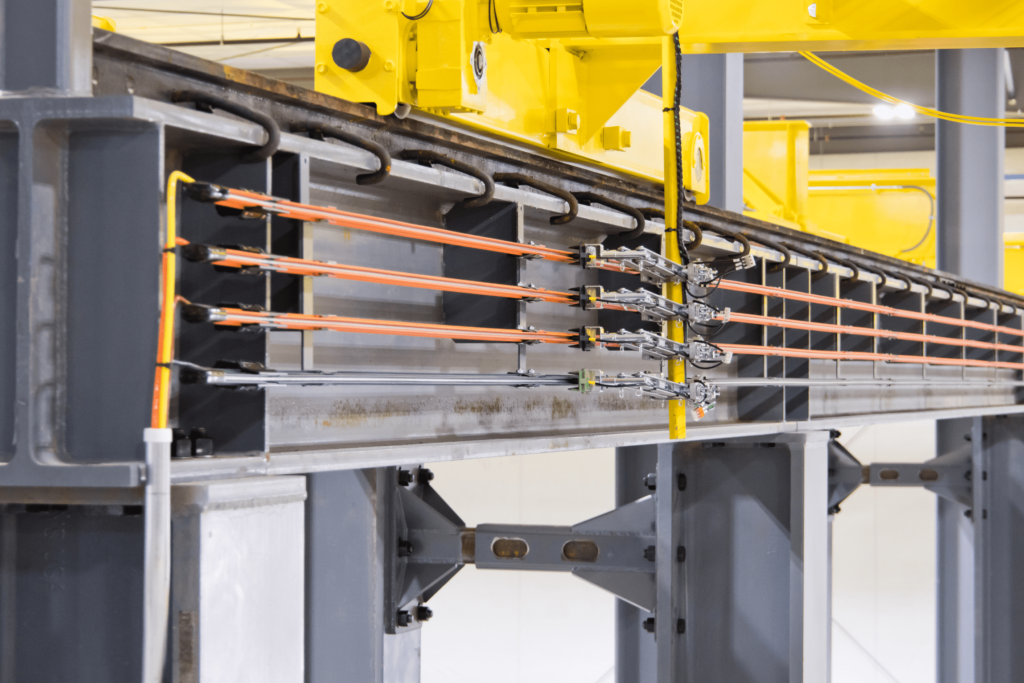

Underhung crane runway systems are used for mounting under hung single girder and under hung double girder cranes. Additionally, most specialty crane systems can also utilize an under hung runway.

AFE Crane suggests to all customers to use patented track as opposed to structural I-beams as a running surface. Although more expensive, patented track provides superior wear resistance to a structural I-beam as the tread of patented track is hardened. Like the top running crane runway, the underhung crane runway can be mounted in various ways.

For example, a freestanding structural system could be used, or the runway could be mounted directly to the bottom of the building structure (if the building design allows for the extra loading). Alternatively, hanger rods can be used to hang under hung runway from an existing structure to lower elevation of the runway.

A freestanding structure is floor supported and can be designed to fit virtually anywhere. These systems can be designed for top running and under hung runways along with monorail and enclosed track systems.

Freestanding structural steel systems are often used if the building structure cannot support the additional load of the system. Freestanding systems can be designed without the use of any bracing, but also can be designed with column bracing which is braced back to the floor (knee braced structure) or with bracing that tie back to the building structure (semi-freestanding structure). Both the knee braced runway and semi-freestanding runway reduce the amount of steel being used making it a more cost-effective system. In most freestanding structures, engineered concrete footings may need to be installed to take the weight of the system.

In building structures designed to withstand the extra forces from overhead cranes, ceiling-mounted structures/runways can be used. These systems are suitable for under hung crane systems with capacities of 5 tons or less.

Ceiling mounted structures are great for keeping shop floor space clear of columns and the ability to have a larger hook coverage area than a freestanding system.

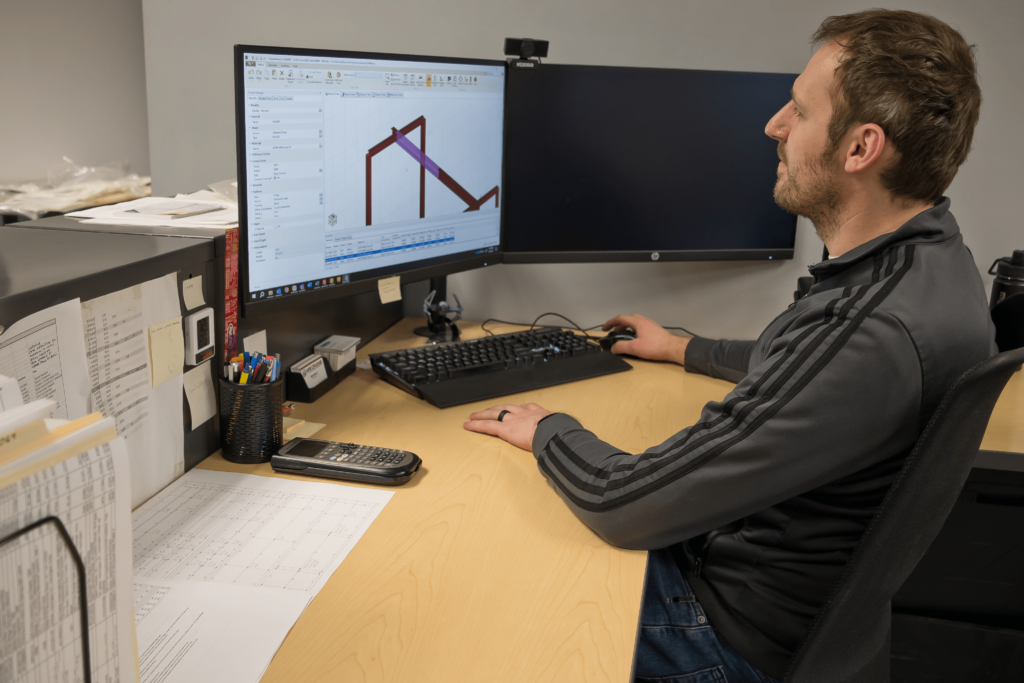

AFE Crane can design, engineer, and fabricate custom crane runway systems and supporting structural steel to fit every customer’s needs. AFE Crane is also able to have our runway and structural system stamped by a Professional Engineer licensed by the National Society of Professional Engineers.

This file category has no files to display

Key factors in designing a crane runway system include the runway type (top running or underhung), load capacity, the number of cranes on the runway, and support spacing to minimize deflection. Additionally, the building structure must be assessed to confirm it can support the runway or if modifications are required.

Crane runways must comply with OSHA Standards (29 CFR 1910.179) for structural integrity, alignment, and safe operation. CMAA Specifications 70 and 74 provide guidelines for the design and maintenance of single and double girder crane runways, while ASME B30.2 emphasizes proper runway design, inspection, and maintenance for safe operation.

Our engineering team will evaluate your operational needs, building structure, and crane specifications to design a runway system that fits your requirements.