Call us today at (800) 728-0818

Patented track rail is a type of precision-engineered rail used in overhead material handling systems. It features a high-strength, hardened steel flange designed to reduce friction, minimize wheel wear, and provide smooth, consistent performance under load.

Patented track rail is a type of precision-engineered rail used in overhead material handling systems. It features a high-strength, hardened steel flange designed to reduce friction, minimize wheel wear, and provide smooth, consistent performance under load.

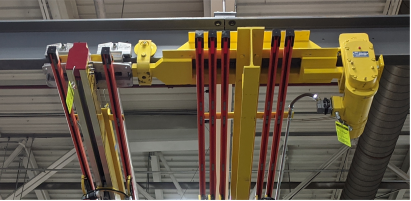

Unlike standard I-beams designed for static loads, patented track rail incorporates a machined flange that enhances durability and system longevity. Its hardened steel construction resists wear over time, even in high-cycle environments, while its lighter weight compared to structural steel reduces building stress and installation costs. AFE Crane integrates patented track rail into crane systems, runways, monorails, and custom trolley configurations where operational efficiency and reduced maintenance are key. These systems are ideal for industrial applications that demand consistent performance and long-term reliability.

Patented track rail is a specialized type of rail designed with a high-strength, precision-machined flange that provides superior durability and consistent performance under load. It is constructed from hardened steel, which allows it to resist wear and maintain its structural integrity over time, even in demanding applications. Unlike standard I-beams, which have flat, uniform flanges and are designed for static loads, patented track rail features a flange specifically engineered to reduce friction and minimize wheel wear, ensuring smooth and reliable operation. Its lightweight design compared to structural steel reduces stress on building structures, lowering installation and maintenance costs.

Patented track systems are widely used in industrial material handling environments where reliability, safety, and efficiency are critical. They are commonly implemented in crane systems, monorail applications, runways, and custom trolley systems to enhance productivity while minimizing maintenance costs.

Patented track cranes provide a durable and efficient solution for overhead lifting applications. Unlike traditional I-beam cranes, the hardened running surface of the patented track reduces rolling friction and extends the life of the system. These cranes are commonly used in manufacturing, warehousing, and assembly line environments where smooth and precise movement is essential.

Patented track monorail systems offer a flexible and efficient means of transporting materials along a fixed path. These systems are ideal for applications where loads must move through specific production processes or where floor space is limited. Unlike standard monorail setups, patented track provides smoother travel and longer system life due to its precision-machined running surface.

Patented track runways serve as the foundation for overhead bridge crane systems, providing a strong and reliable support structure for lifting and material transport. Compared to standard I-beam runways, patented track runways offer reduced friction, greater durability, and longer operational life, making them an excellent choice for demanding industrial applications.

Trolleys and carriers are essential components of patented track systems, facilitating smooth and efficient load movement. Designed for durability and precision, these components ensure optimal performance for overhead cranes, monorails, and runway systems. Their hardened trolley wheels and specialized bearings reduce rolling resistance, enhancing efficiency while extending system life and reducing wear on trolley.

Ideal for moving materials and work-in-progress throughout production areas.

Efficiently handle inventory, facilitate order picking, and optimize storage space.

Support assembly line operations, move parts, and manage heavy components.

Handle large and delicate aircraft components with precision.

Used in steel mills, foundries, and other demanding environments to move heavy loads.

Where cranes are used frequently and for demanding tasks.

Patented tracks excel at handling substantial weights efficiently and safely.

The strength-to-weight ratio allows for longer distances between supports, maximizing workspace.

Patented tracks can be configured to create intricate monorail systems or integrated into overhead crane setups.

The durability and reliability of patented tracks reduce the need for maintenance and repairs.