Call us today at (800) 728-0818

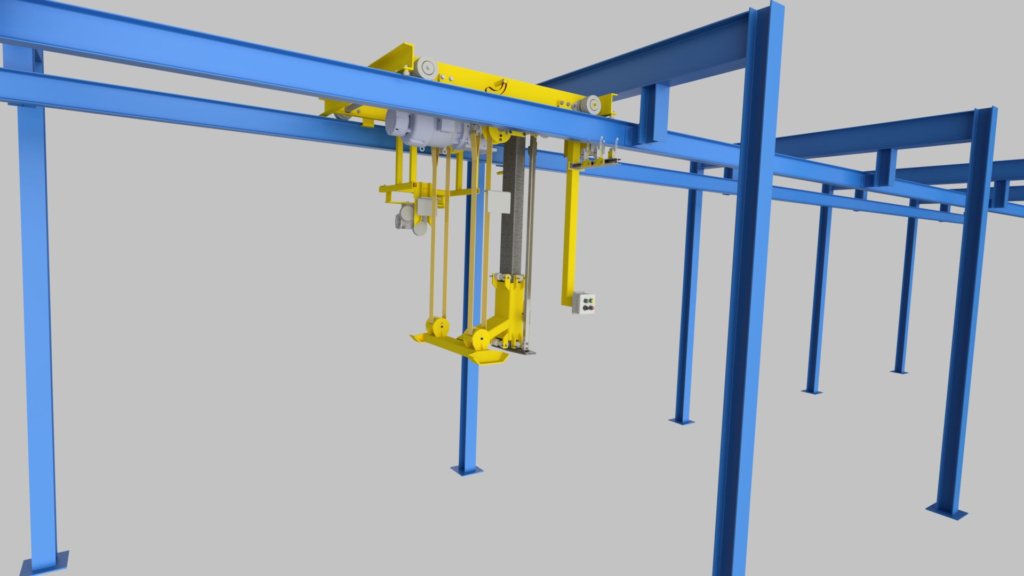

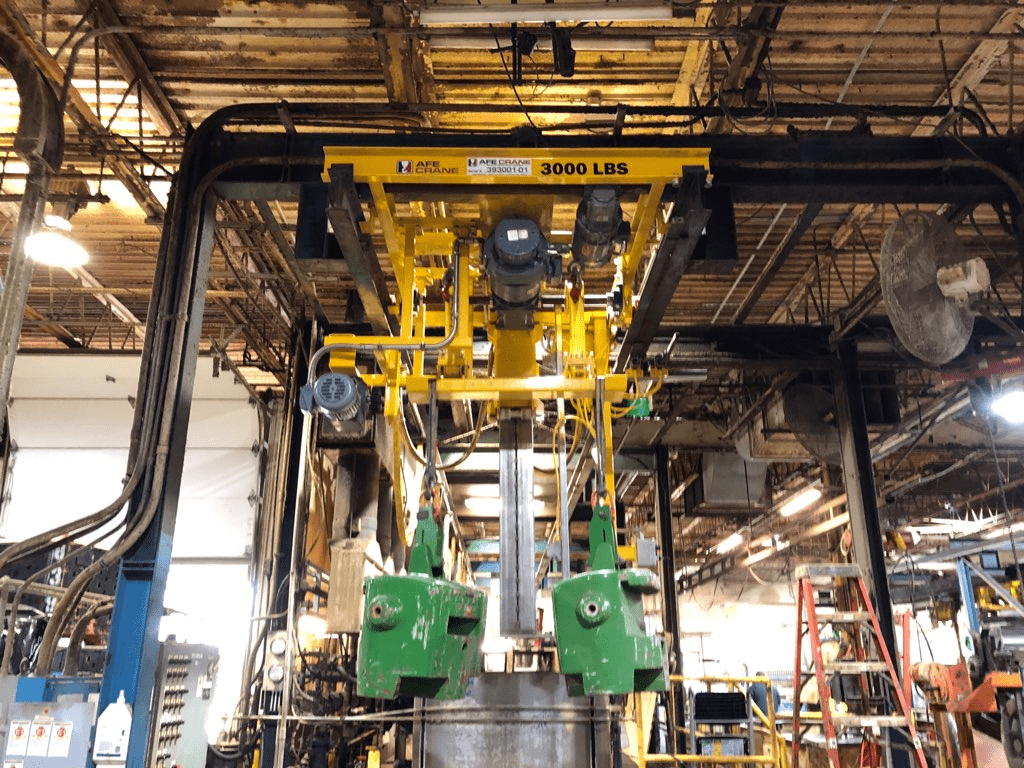

A process bridge crane is a highly specialized overhead lifting system designed for continuous, high-efficiency material handling in demanding industrial environments. Unlike standard bridge cranes, process cranes are engineered for specific applications where precision, durability, and automation are critical.

A process bridge crane is a highly specialized overhead lifting system designed for continuous, high-efficiency material handling in demanding industrial environments. Unlike standard bridge cranes, process cranes are engineered for specific applications where precision, durability, and automation are critical.

Process cranes are custom-engineered to match the specific operational needs of each facility, often incorporating automation to streamline workflow and minimize manual labor. Factors such as load capacity, span, lifting speed, and environmental conditions guide the design process. These systems frequently include automated controls, variable frequency drives, condition monitoring, and redundant safety features to maximize uptime and ensure consistent performance. Common applications include steel production, automotive manufacturing, paper mills, and warehousing, where cranes are required to execute repetitive and precise lifting tasks. With specialized attachments and tailored programming, AFE Crane delivers high-duty cycle process cranes that enhance productivity in even the most demanding industrial environments.

Process cranes are custom-engineered to match the specific operational needs of each facility, often incorporating automation to streamline workflow and minimize manual labor. Factors such as load capacity, span, lifting speed, and environmental conditions guide the design process. These systems frequently include automated controls, variable frequency drives, condition monitoring, and redundant safety features to maximize uptime and ensure consistent performance. Common applications include steel production, automotive manufacturing, paper mills, and warehousing, where cranes are required to execute repetitive and precise lifting tasks. With specialized attachments and tailored programming, AFE Crane delivers high-duty cycle process cranes that enhance productivity in even the most demanding industrial environments.

Process cranes are highly adaptable and can be customized to meet the specific requirements of various industries. From specialized lifting attachments to advanced automation, these modifications enhance efficiency, safety, and precision. Customization ensures that the crane seamlessly integrates into existing workflows while maximizing performance and reliability.

Custom grabs, magnets, tongs, vacuum lifters, and C-hooks designed for specific materials.

Single or dual hoists, synchronized lifting, and precision positioning for complex operations.

Programmable logic controllers (PLCs), variable frequency drives (VFDs), and remote operation capabilities.

Overload protection, collision avoidance systems, redundant braking mechanisms, and operator-assist technology.

Heat shielding, corrosion-resistant coatings, explosion-proof designs, and weatherproof enclosures for harsh environments.

Anti-sway technology, adaptive speed control, and automated load positioning for high-precision applications.

Reinforced structures, high-performance bearings, and wear-resistant materials for demanding applications.

If you don’t see the customization you’re looking for, AFE Crane can design a solution to fit your specific needs. Contact us to discuss your requirements.

Each Process Crane System designed by AFE Crane is custom-engineered to meet the specific requirements of your application. Due to this level of customization, standardized vendor specifications are not available. Instead, our team works closely with trusted suppliers to source high-quality components that align with your system’s unique design and operational needs.

This file category has no files to display

This file category has no files to display

Unlike standard overhead cranes, process cranes are designed for continuous operation in demanding environments. They typically feature automated controls, high-duty cycle motors, and precision positioning to maximize efficiency and reduce downtime.

Yes! AFE Crane offers semi-automated and fully automated process cranes with advanced control systems, including Programmable Logic Controllers (PLCs), Variable Frequency Drives (VFDs), and remote monitoring. These features improve safety, accuracy, and efficiency in industrial operations.

Yes! AFE Crane offers modernization and upgrade services to enhance older process cranes with new control systems, automation features, improved lifting components, and energy-efficient solutions. This extends the lifespan of existing cranes and increases productivity.