Call us today at (800) 728-0818

An overhead bridge crane is a type of industrial lifting equipment consisting of a horizontal bridge that moves along elevated parallel runways. A hoist trolley travels across the bridge, allowing for controlled lifting and horizontal movement of loads.

Overhead bridge cranes are industrial lifting systems commonly used in factories, warehouses, and manufacturing facilities. They offer a reliable and space-saving solution for handling large or repetitive loads. AFE Crane specializes in designing and installing both top running and underhung systems to match your building structure, lifting capacity, and workflow. From initial design to final installation, our team delivers turn-key crane solutions built to enhance safety, improve material flow, and maximize floor space in your facility.

A Top Running Single Girder Crane (TRSG) is the most common type of overhead bridge crane. It is a versatile bridge crane that can be utilized for a wide variety of industries. TRSG overhead cranes can be built with capacities up to 15 tons and spans up to 98 ft. Typically, TRSG crane capacities vary between 5 and 10 ton. With these capacities, the bridge beam is typically a wide flange structural member. Most cranes that exceed a capacity of 10 ton with a span greater than 60 ft will utilize a box girder bridge beam.

The hoist/trolley used on a TRSG crane is always an under hung style trolley which runs on the bottom flange of the bridge beam. For this reason, a TRSG crane is not the best crane option if facility headroom is a major issue. See Top Running Double Girder cranes if headroom is a key factor.

Top Running Single Girder bridge cranes use end trucks that operate on ASCE rail or square bar that is attached to the top of the runway beam. The runway for a TRSG crane can either be building supported (if building is suitable) or by using a freestanding runway system. The runway beams generally span across a full building bay. One downside to any top running bridge crane is that the hoist/trolley is not able to travel beyond the runway, limiting the hook coverage area of the hoist/trolley. See Under Hung Single and Double Girder cranes if maximum hook coverage is required.

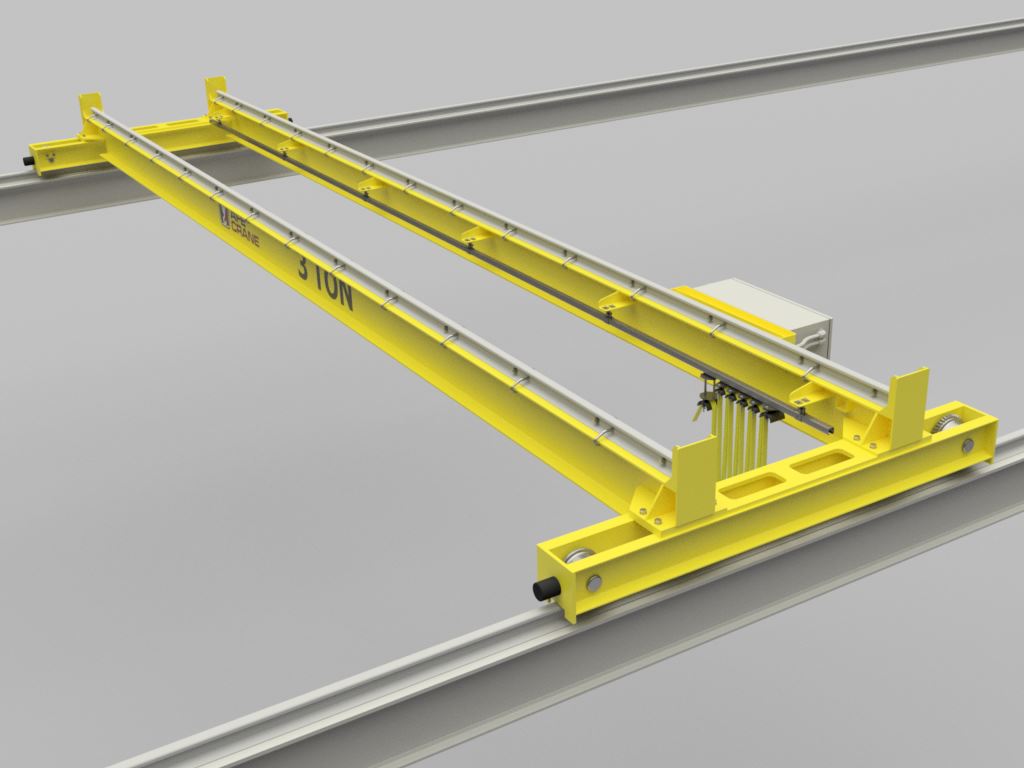

A Top Running Double Girder (TRDG) bridge crane is similar to a Top Running Single Girder Crane (TRSG) crane, except for an additional bridge beam. The additional girder increases the capacity capability to 30 tons or larger.

With the addition of a second bridge beam, both top running and under hung hoist trolleys can be used. For most cases, a TRDG crane can have the best high hook (compared to other crane styles) because the hook can be mounted between the two bridge beams. Double girder cranes also have a better means of handling large moments caused by stackers, part manipulators or components other than a hook.

An Under Hung Single Girder (UHSG) bridge crane (a.k.a. under running crane) is the most common type of bridge crane for low lifting capacities. Being one of the most economical styles of bridge cranes, these cranes are most popular in high production rate facilities and assembly plants. UHSG cranes are typically built with spans up to 60 ft and capacities up to 10 tons or more, depending on the span. Just like TRSG cranes, UHSG cranes use a wide flange structural bridge beam and an under hung style trolley running on the bottom flange of the bridge beam.

Under Hung Single Girder overhead bridge cranes run on the bottom flange of a structural or patented track runway beam. Because of this, UHSG cranes typically take up a fair amount of headroom in the customer’s facility. More headroom can be achieved by modifying, or coping, the beam to end truck connection, however the hoist/trolley end approach may be reduced.

Hoist/trolley end approach is increased on UHSG cranes, so much so that the hoist hook can travel under the runway. Additionally, this style of crane can also be designed with a cantilever or projecting (telescoping) bridge that will allow the hoist to travel up to 25% of the bridge length beyond the centerline of the runway. UHSG cranes that use patented track bridge beams can also latch onto spur rails and/or monorail systems to improve workflow and increase productivity. Another advantage of UHSG cranes is the option to add additional end trucks (and runways) to the crane. This allows cranes to have a higher capacity and/or large span while using a smaller, less costly bridge beam. Using more than two end trucks also improves the crane’s runway system by reducing hanger loads. The runways for UHSG cranes can be freestanding and ceiling mounted (if building is suitable).

An Under Hung Double Girder (UHDG) bridge crane shares the same traits as an UHSG crane. The extra bridge beam allows the crane to reach up to 20 tons or larger.

With the addition of a second bridge beam, both top running and under hung hoist trolleys can be used. For most cases, a UHDG crane can have a better high hook than a UHSG because the hook can be mounted between the two bridge beams. Double girder cranes also have a better means of handling large moments caused by a stacker, part manipulators or components other than a hook.

AFE Crane offers a wide range of customization options to ensure that your overhead bridge crane meets the specific needs of your facility. From performance enhancements to safety features, our tailored solutions provide flexibility, efficiency, and reliability for your lifting operations.

Choose from CMAA Class A through Class F to match your application’s usage requirements.

Single speed, two speed, or infinitely variable speed controls for bridge, trolley, and hoist motions.

Standard pendant control, walk-away pendant, or wireless radio controls for enhanced operational flexibility.

Coped bridge girder at end truck connection to optimize headroom and maximize lift height.

Precision slowdown and stop functions for hoist, trolley, or bridge travel to enhance safety and control.

Integrated systems to prevent collisions between multiple cranes operating in the same bay.

Advanced automation options for increased efficiency, repeatability, and reduced operator intervention.

If you don’t see the customization you’re looking for, AFE Crane can design a solution to fit your specific needs. Contact us to discuss your requirements.

AFE utilizes a large comprehensive supply chain for materials and parts in addition to establishing long term relationships with our parts vendors. This relationship helps us to expedite parts so that your equipment can be repaired quickly.

This file category has no files to display

This file category has no files to display

Enhancing Safety with Projecting Lights In busy industrial work environments, ensuring the safety of employees and equipment is a top priority. AFE Crane recommends implementing

Investing in an overhead crane is a major decision that impacts your facility’s efficiency, productivity, and safety. The right crane can enhance operations, while the

Overview In today’s fast-paced manufacturing environment, minimizing downtime is essential for staying competitive. With Intelli-Connect™ Mobile, you can effortlessly program, maintain, monitor, and troubleshoot overhead

Customization is key at AFE Crane when it comes to overhead lifting solutions. In this edition of Overhead Lifting Insights, learn about the advantages of

At AFE Crane, we prioritize reliability, durability, and precision engineering in every overhead lifting solution we deliver. Our bridge cranes are meticulously designed, manufactured from

Improving efficiency and safety in material handling is essential for staying competitive in today’s market. AFE Crane offers automation and smart crane technologies to help

An overhead bridge crane is a type of material handling system that consists of parallel runways with a bridge spanning the gap. It moves loads using a hoist that travels along the bridge, allowing for precise lifting and positioning.

An overhead bridge crane is a permanently installed system that moves along parallel runways mounted to a building’s structure, making it ideal for indoor use in factories and warehouses where maximizing floor space and handling heavy loads is essential. In contrast, a gantry crane is a self-supporting structure with legs that run on wheels or rails, allowing it to be used in outdoor environments, temporary job sites, or locations without existing support structures. The main difference is that bridge cranes rely on the building for support, while gantry cranes are freestanding and portable.

Key factors include: