- Wire Rope & Chain Hoist

- Ergonomic Balancers

- Workstation Cranes

- Crane Sets & Components

Call us today at (800) 728-0818

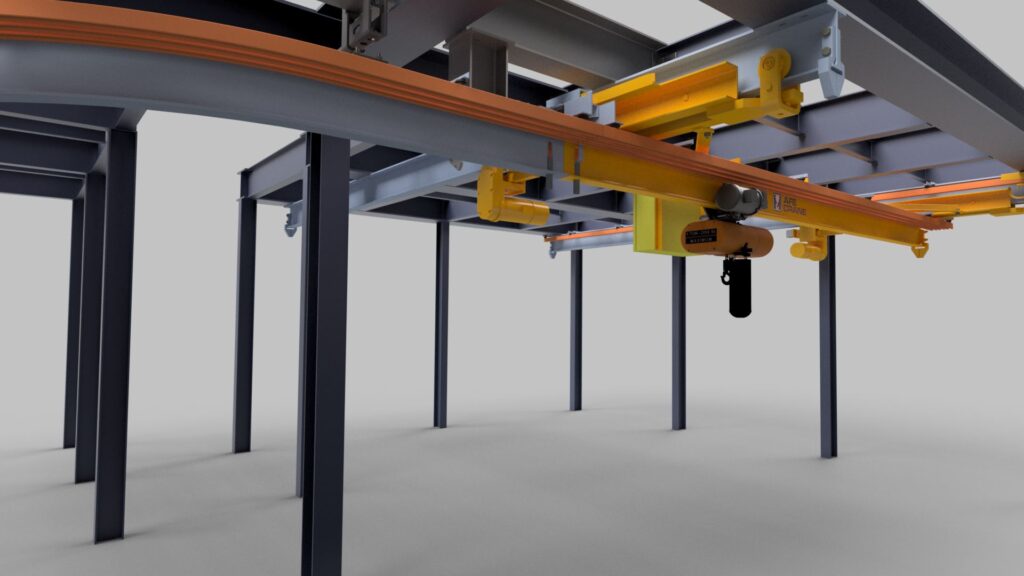

Interlock Transfer Crane Systems are designed to facilitate the seamless movement of materials between multiple bridge cranes operating in adjacent or connected bays. Using a specialized interlocking mechanism, these systems enable a hoist to travel safely and efficiently from one crane to another without the need for manual handling. This capability extends the operational range of overhead cranes, optimizing workflow efficiency and reducing downtime. By integrating interlock technology, facilities can enhance productivity while maintaining a high level of safety in their material handling operations.

Interlock Transfer Crane Systems are designed to facilitate the seamless movement of materials between multiple bridge cranes operating in adjacent or connected bays. Using a specialized interlocking mechanism, these systems enable a hoist to travel safely and efficiently from one crane to another without the need for manual handling. This capability extends the operational range of overhead cranes, optimizing workflow efficiency and reducing downtime. By integrating interlock technology, facilities can enhance productivity while maintaining a high level of safety in their material handling operations.

AFE Crane custom-engineers Interlock Transfer Crane Systems to meet the unique needs of various industries, including manufacturing, aerospace, and heavy equipment assembly. Our solutions are designed to support specific load capacities, spans, and environmental conditions, ensuring reliable performance in demanding applications. Whether transferring materials across multiple bays or integrating with existing monorail systems, our interlock solutions provide a seamless and efficient method for handling complex lifting operations.

Interlock and transfer cranes are highly adaptable to meet the specific needs of various material handling applications. Customization ensures seamless operation, whether integrating multiple cranes, accommodating unique facility layouts, or automating processes for efficiency and safety. Available customization options include:

Ideal for light and medium-duty applications, a manually engaged latch allows operators to control crane transfers with minimal complexity.

For heavier-duty systems, a motorized latch enhances efficiency by automating the engagement and release of the interlock mechanism.

Systems can be designed with multiple cranes, monorail sections, or interlocking paths to optimize material flow within a facility.

Depending on operational needs, hoists can be electric, manual, or air-powered, offering flexibility in lifting capacity, precision, and duty cycle.

For advanced sequencing and interlocking functions, programmable logic controllers (PLCs) automate crane movements, improving repeatability and reducing operator intervention.

If you don’t see the customization you’re looking for, AFE Crane can design a solution to fit your specific needs. Contact us to discuss your requirements.

Each Interlock Transfer Crane System designed by AFE Crane is custom-engineered to meet the specific requirements of your application. Due to this level of customization, standardized vendor specifications are not available. Instead, our team works closely with trusted suppliers to source high-quality components that align with your system’s unique design and operational needs.

A latching crane is an overhead crane system designed with a mechanical or automated latching mechanism that allows it to securely connect to a designated transfer station, bridge crane, or runway extension. This enables seamless material transfer between different crane systems or workstations.

The latching mechanism can be manual, semi-automatic, or fully automated. It typically consists of mechanical stops, hooks, or electronic sensors that engage when the crane reaches a predetermined transfer point. This allows the load to be safely handed off to another crane or track system.

Yes! AFE Crane specializes in customizing and retrofitting latching mechanisms into existing overhead crane systems. Our team evaluates your facility layout and operational needs to determine the best integration approach.