Understanding Upper Limit Switches

One of the most crucial safety features in any wire rope hoist system is the upper limit switch. Designed specifically to halt upward travel of the hook block, this component prevents “two-blocking,” an event where the hook block collides with the drum. Without a reliable upper limit switch, severe equipment damage, wire rope failure, and even dangerous load drops could occur.

Why Upper Limit Switches Matter

In scenarios without a functioning upper limit switch, there’s a substantial risk of equipment failure and serious safety hazards. An unchecked hoist can inadvertently drive the hook block into the drum, leading to significant mechanical damage and potential failure of the wire rope. The consequences can be catastrophic, emphasizing the necessity for rigorous adherence to safety standards.

US vs. European Hoist Standards

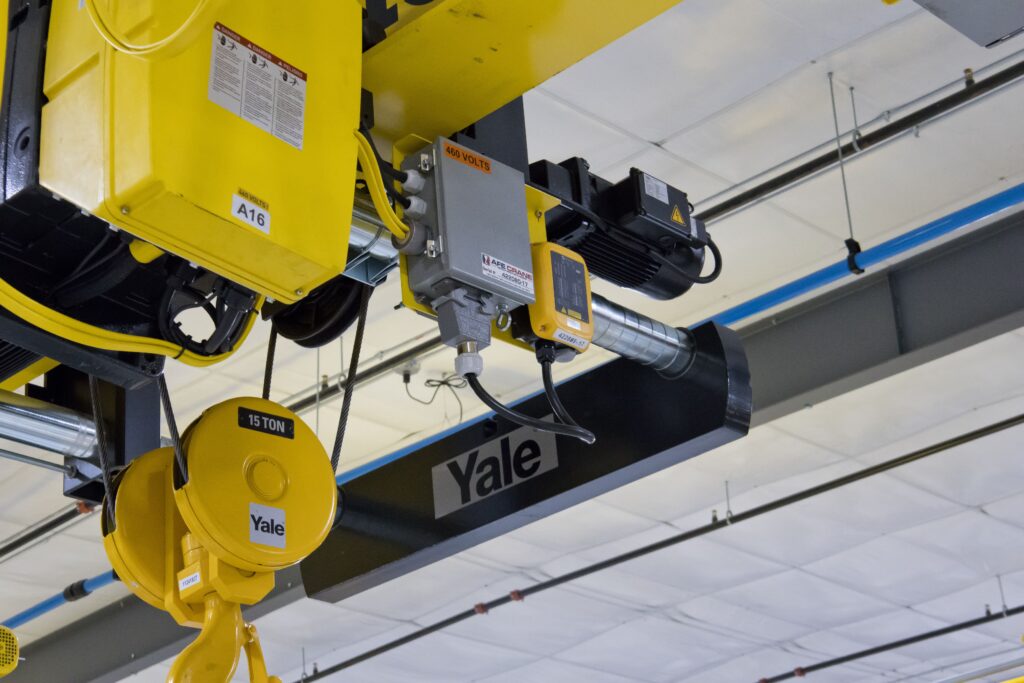

The methods for achieving safe operation vary significantly between US and European hoist standards. American manufacturers typically follow the guidelines outlined in ASME B30.16, mandating that hoists must include an independent method to prevent upward overtravel. US hoists generally employ a weight or lever-operated upper limit switch as standard, with an optional geared limit switch for additional protection. Renowned manufacturers adhering to these standards include Acco, Detroit Hoist, Yale-Shawbox, ElectroLift, and Saturn.

European standards, however, usually rely exclusively on a geared limit switch as the primary method of controlling upward travel. Notable manufacturers such as Demag, Harrington, Street, Stahl, and R&M implement this method, highlighting a fundamental difference in design philosophy.

Lessons Learned: The Importance of Redundancy

At AFE Crane, we’ve experienced firsthand the importance of comprehensive safety features. A few years ago, a hoist designed according to European standards experienced a geared limit switch failure. Fortunately, the attentive operator manually intervened before a critical failure could occur, avoiding potentially severe consequences.

This incident underscores our belief that the safest strategy is a dual-approach: employing hoists compliant with ASME B30.16 and incorporating an additional geared limit switch for redundancy. This combined approach greatly reduces risk, ensuring operational safety and equipment longevity.

Choosing the Right Hoist for Maximum Safety

When selecting a wire rope hoist, always prioritize systems with robust and redundant upper limit switches. Adhering strictly to ASME B30.16 guidelines and opting for the additional protection of a geared limit switch ensures your operations remain safe, reliable, and compliant with leading safety standards.

Conclusion

Upper limit switches are not just an option—they are an essential safeguard. By implementing comprehensive safety measures and prioritizing compliance with proven standards like ASME B30.16, companies can significantly enhance equipment safety, prevent costly damages, and protect their workforce. At AFE Crane, safety and reliability always come first, guiding every recommendation and solution we provide.