- Variable Frequency Drive

- Advanced Crane Controls

- Encoders & Accessories

Call us today at (800) 728-0818

Crane system controls serve as the critical interface between the operator and the crane, enabling precise, safe, and efficient operation. These controls allow operators to direct movement, raise or lower the hoist, adjust speeds, and manage the crane’s overall function by translating input into electrical signals that power the crane’s motors and brakes. In addition to executing commands, modern control systems provide real-time feedback on crane status, including position, load weight, and system alerts, while integrating essential safety features such as emergency stop functions and overload protection.

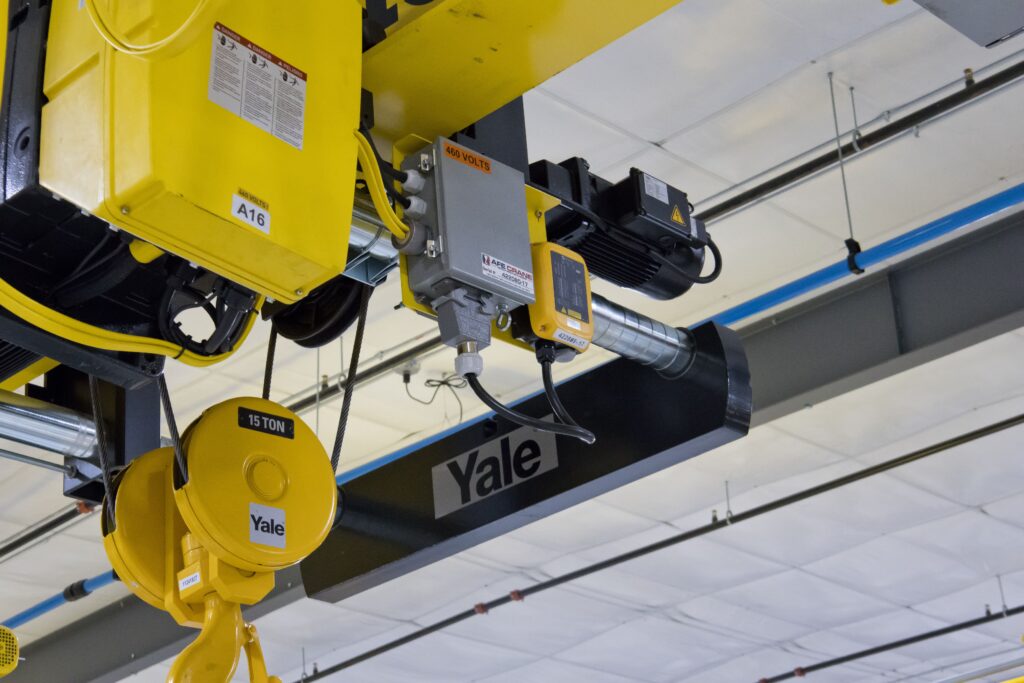

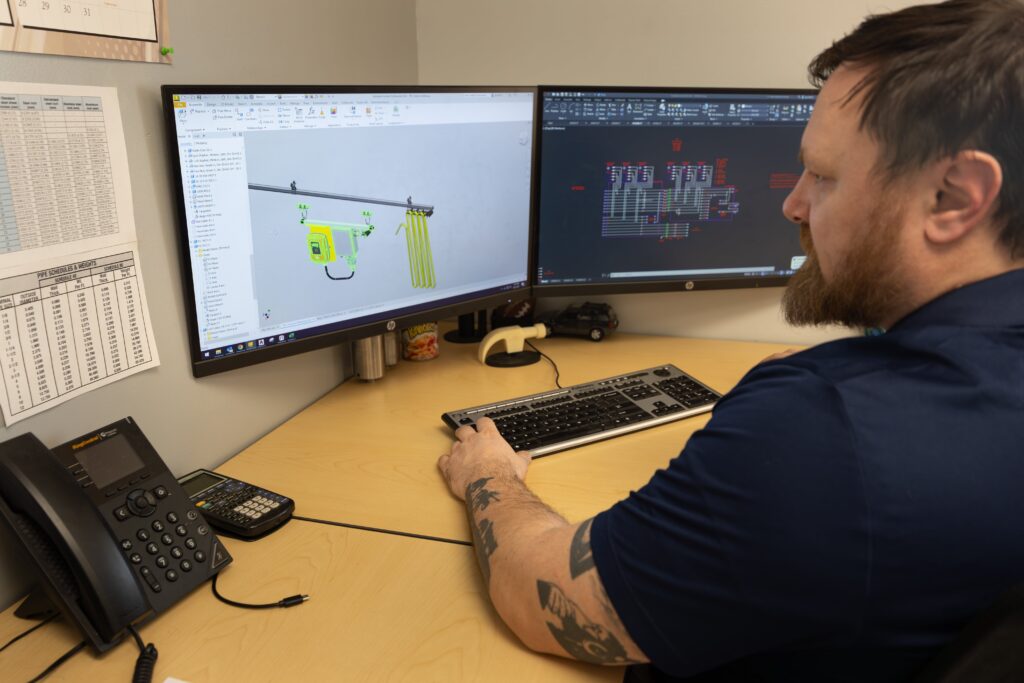

AFE Crane offers a full range of standard and advanced system controls to support safe and reliable overhead crane operations. Our solutions include everything from basic contactor-style controls to sophisticated Variable Frequency Drives (VFDs), along with pendant and radio control options, motion control systems, and customized power supply configurations—each designed to match specific application requirements and improve overall crane performance.

Contactor controls are the most simple and economical way to control motors common to overhead bridge cranes. A forward and reverse control signal is provided to reversing contactors allowing 3-phase power to be sent to the motor. However, contactor controls can be hard to control because they only have two states: on and off.

The best way to control drive and hoist motors is with a Variable Frequency Drive (VFD), also known as Adjustable Frequency Drives (AFD). The primary advantage of VFD’s is the ability to program different parameters (or settings) into the device. These parameters can be changed by the user to adjust the minimum & maximum speed, acceleration time, and maximum allowable motor amperage just to list a few.

A VFD can also be set to two-step infinitely variable. This allows operator can set the travel speed to anywhere within the min and max speed settings while only using the standard two-speed button configuration. VFD’s can also be programed to slow down or stop motion if the VFD receives an additional signal from an additional sensor, eliminating relays for small control schemes. Similar to contactors, VFD’s are supplied with control signals and come in an array of versions and sizes, which are sized by the horsepower (of Full Load Amps) of the motor(s) it drives.

Cranes and other overhead lifting devices typically use a pendant for inputting hoist, trolley, crane, and any other controls into the system. Pendants are typically mounted directly under the hoist via pendant cord & strain relief, so the pendant is always by the hoist hook. This is the most economical and best way to mount a pendant, unless one is lifting large, long, or unusual loads, then a walk-away pendant is the better option. Walk-away pendants are mounted on a separate festoon track along the bridge’s length. This allows the pendant (and crane operator) to be at one end of the crane and the hoist hook to be at the other, this keeps the operator a safe distance from the load.

More common in the overhead material handling industry are radio control systems. Like an RC car, a crane operator can stand anywhere (within range) and operate it wirelessly with a handheld transmitter. This allows the operator to be completely safe by not standing under or close to the lifted load. Many brands of radios also have additional features that can make lifting safer and easier in large assembly plants. When using a radio, a signal light, horn, or other warning device is required by ASME B30 standards.

Powering cranes are typically done in one of three ways: manual, electrical, or pneumatic. Manually operated cranes are the most economical option due to the lack of electrical or pneumatic control systems required. However, manually operated hoists, trolleys, and cranes use a chain fall that can clutter floor space and is slow and timely to use. These systems are typically best in small shops/garages or where 2-3 lifts are performed each week.

Electricity is by far the most common way to control cranes in small shops and garages but also in large factories and assembly plants. Typically, cranes are designed to use 3-phase power at 460 volts. Other voltages can be used as well such as 575 and 230 volts, 120 or 240 single phase can also be used but are not as common. The amperage draw can vary depending on the size/capacity, number of motors, and other controls being used, but is typically 30 amps or less.

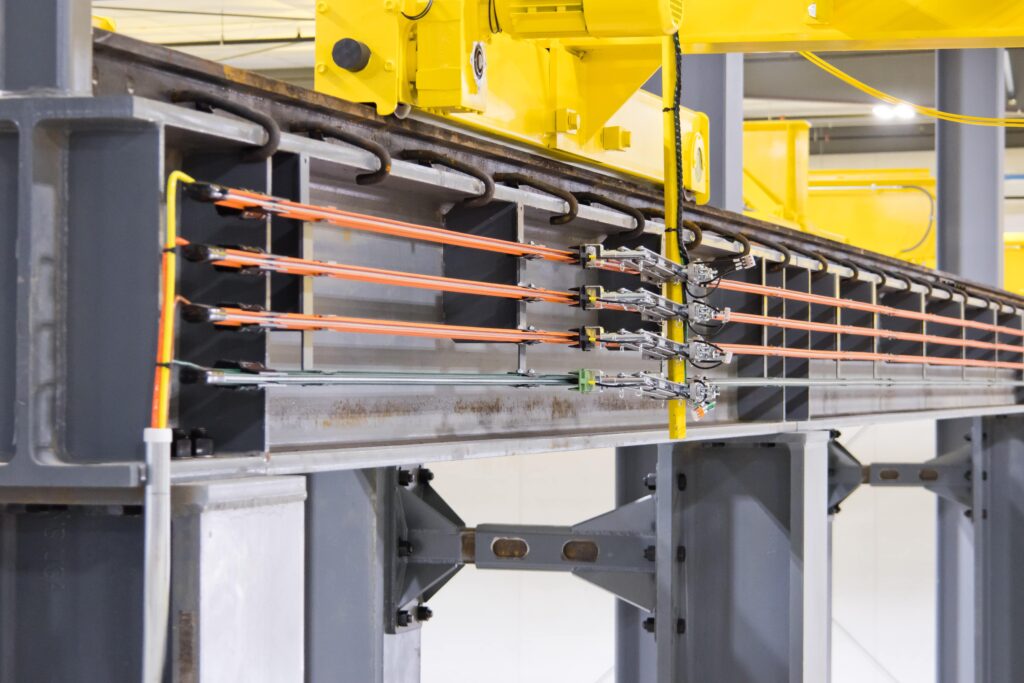

Supplying electricity to cranes is most commonly done by a conductor bar system. Four runs (3 phases & 1 ground) of conductor bar are mounted to the length of the runway and mating collector assemblies are mounted to the crane. These collectors pick up the electricity off the conductor bars and feed the crane systems. For areas where the potential of arching or sparking is not permitted, a rigid track festooning and flat cable would be used.

Pneumatic controlled cranes are run using compressed air from the customer’s compressed air system. A typical air hoist needs a system pressure of 90-125 psi and at least 50 cfm’s of airflow to run properly. Depending on the volume of compressed air required and other factors, a self-retracting coiled hose supported on a taut wire festoon or a rigid track festoon trolleys and a flexible rubber airline would be used in-leu of a flat cable festoon system.

About all motions of overhead lifting (hoist, trolley, and crane) can facilitate one, two, or more speeds. The number of speeds a motion has does not relate to its top lifting speed. For example, if a trolley is specified to travel at a maximum of 60 fpm, a 2-speed control system can operate that hoist at a slower 1st speed, perhaps 15 fpm for 1st speed and 60 fpm for 2nd. If a 3-speed system were used with the same hoist, the 1st speed could be at 15 fpm, 2nd at 45 fpm, and 3rd at the max of 60 fpm. When contactor controls are used, these speeds are set by the motor manufacturer. When a VFD is used with multi-speed controls, AFE crane & the end user can set all speeds if they do not exceed the maximum speed of the motor. With the use of VFD’s and Infinitely Variable controls on the rise, 2-speed systems are typically the most common as when using a single speed system the load may start to swing, becoming dangerous for the operator to control. Many systems have 2-speed motion for all directions which allows the operator to make accurate/precise movements.

In a situation where multiple cranes/hoists need to be used simultaneously by a single operator, an A-B-Both system may need to be implemented. An A-B-Both system allows one operator to operate hoist A, or hoist B, or both hoist A & B. A selector switch is normally on the radio transmitter or pendant for easy selection from the operator. Using multiple hooking points and an A-B-Both control system is a safe means of lifting and moving items using multiple hoists. This eliminates the need for the operator to use both hands for controls and faulty communications between two operators. A-B-Both controls can also be applied to separate cranes using the same runway. More complex systems can be used when more components are used, for example Crane 1 with Hoists A & B, and Crane 2 with Hoists C & D.

AFE Crane provides custom system controls designed to enhance safety, efficiency, and automation in overhead crane operations. These solutions include collision avoidance systems, end approach slowdown and stop features, automation controls, and other advanced options tailored to meet specific operational needs.

Collision avoidance systems can keep cranes isolated without mechanical switches or devices. These systems can be used to prevent impacts between cranes and other obstructions. Reducing impacts can improve operator safety and reduce the wear and tear on equipment. Collision avoidance systems can also be used to maintain a minimum distance between cranes to prevent overloading runways and support structure. Keeping cranes segregated used to be done with bumpers, crane spacers, or limit switches. A collision avoidance system typically consists of an optical sensor and a reflector. The reflector is mounted on the crane or object that will be detected. These sensors can detect two distances which can easily be programmed for different distances. This can allow you to use a slowdown and stop function at different distances. Signal lights or alarms can be used to indicate when cranes or objects are being detected. Collison avoidance systems can be installed on new cranes and can be retrofitted to existing crane systems. The sensor can be integrated into cranes using a VFD or contactor controls.

Crane segregation systems utilize the same technology as collision avoidance systems but are specifically designed to prevent cranes from overloading the runway and its supporting structure. By maintaining designated operating zones, these systems help control crane positioning and spacing without the need for mechanical limit switches or physical barriers. Optical sensors detect nearby cranes and trigger programmed slowdown or stop functions, ensuring safe and efficient operation. These systems can be integrated with VFD or contactor controls and are available for both new and existing crane systems.

Adding end approach slowdown & stop controls to a trolley or bridge adds many benefits to crane systems and employee safety. Without this added feature, the only means of stopping a crane or trolley is with the use of mechanical end stops. Depending on the size of crane and load being lifting, running into the end stops can put large and unnecessary impact forces on the trolley, crane, runway structure, and even the building. End approach slowdown and stop can be installed on either bridge and/or trolley motion. When operational, the bridge (or trolley) will slow down and stop right before the bumpers hit the end stops. This will eliminate most of the systems’ impact forces causing less wear and tear on the equipment. Additionally, this will help reduce load swing by extending the slowdown area. Lastly, end approach slowdown and stop will help prevent unnecessary wear between the wheels and tread by preventing a “burnout” situation between the two surfaces, causing wear in the tread surface.

AFE utilizes a large comprehensive supply chain for materials and parts in addition to establishing long term relationships with our parts vendors. This relationship helps us to expedite parts so that your equipment can be repaired quickly.

This file category has no files to display

This file category has no files to display

This file category has no files to display

The Role of VFD Technology in Overload Protection Variable Frequency Drives (VFDs) represent a significant advancement in overload protection technology for crane and hoist systems.

Radio control systems have rapidly become an essential tool in the overhead material handling industry due to their advanced features and superior flexibility compared to

In modern industrial environments, efficient and safe material handling is crucial for maintaining productivity and ensuring worker safety. The ProPath™ Automated Workstation Crane stands out

Understanding the Risks of Hoist Side Pull Overhead cranes play a crucial role in industrial operations, lifting and transporting heavy loads with precision. However, improper

Enhancing Safety with Projecting Lights In busy industrial work environments, ensuring the safety of employees and equipment is a top priority. AFE Crane recommends implementing

AFE CRANE is a proud distributor of Magnetek FLEX EX2 Series Radio Remote Controls The Flex EX2 series of radio remote controls offer even more

AFE Crane provides a variety of control options for overhead cranes, including pendant controls, radio remote controls, and custom designed systems. We also offer variable frequency drives (VFDs) for smooth and precise load handling, as well as programmable logic controllers (PLCs) for advanced automation and safety features.

Yes! AFE Crane specializes in control system upgrades and modernizations. Whether you need to replace outdated pendant controls with a wireless remote system or integrate a more advanced VFD, we can design a custom solution to enhance your crane's performance.

A VFD is an electronic device that controls the speed and torque of an electric motor by adjusting the frequency of the power supply. In crane applications, VFDs provide smooth acceleration and deceleration, reduce mechanical wear, improve load control, and enhance energy efficiency.