Call us today at (800) 728-0818

Structural steel fabrication is the process of transforming raw steel into the components used to create large-scale structure is a specialized subset of metal fabrication that focuses on creating steel components used in the construction industry.

Crane manufacturing and installation is our core business where we focus on structural steel fabrication for the construction of Crane Runways and its supporting structure. Our processes, equipment and experienced staff also enable us to offer fabrication services for structural components including beams, columns, headers, and support structure for a wide range of structural applications.

AFE Crane can design, engineer and fabricate custom crane runway systems and supporting structural steel to fit every customer’s needs. AFE Crane is also able to have our runway and structural system stamped by a Professional Engineer licensed by the National Society of Professional Engineers.

Horizontal structural elements supporting loads.

Vertical supports transferring loads to the foundation.

Main horizontal load-bearing members in a structure.

Structural frameworks composed of interconnected elements.

Diagonal members providing lateral stability.

Suspension elements used to support crane runways and structural loads.

Reinforcement elements ensuring stability and strength in crane system applications.

For pedestrian access.

Intermediate floors in industrial buildings.

For shade and protection.

For security and enclosure.

Tailored to specific project requirements.

The process of structural steel fabrication is a meticulous one, requiring precision, expertise, and adherence to strict standards. Here’s a breakdown of the steps we use at AFE Crane.

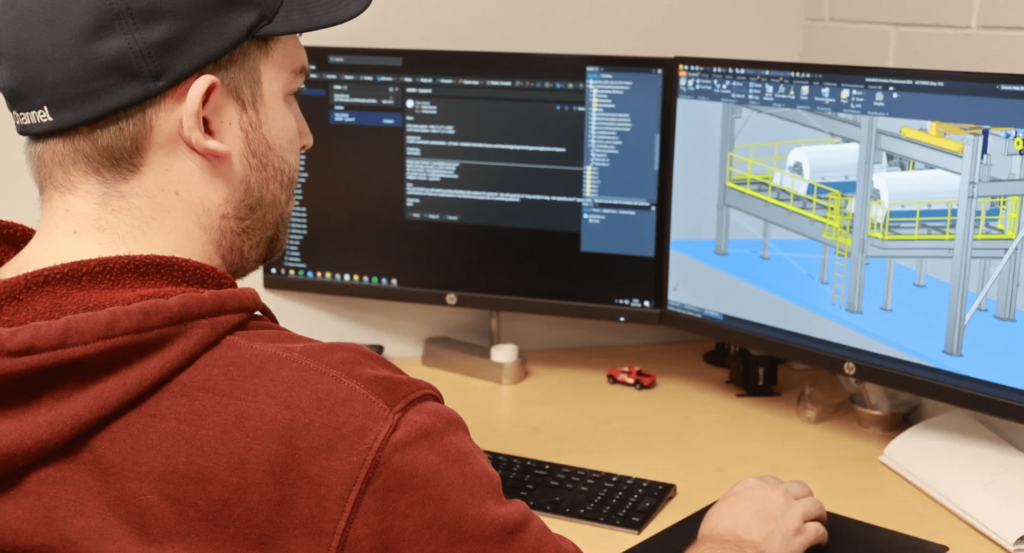

The process begins with detailed CAD drawings and engineering blueprints outlining the structure’s dimensions, load-bearing requirements, and material specifications.

We understand the importance of project management to monitor and insure each step of the process is complete and moving forward to the next step. Project management is how AFE keeps our customers up to date on the status of their construction project and final product.

Steel Selection & Material Sourcing: Appropriate steel grades and sections are chosen based on the design requirements and load-bearing capacities. Steel is procured from reputable suppliers, ensuring it meets the specified quality standards.

Painting or Coating: Steel components may undergo painting or coating for corrosion protection or aesthetic purposes.

At AFE Crane, we prioritize reliability, durability, and precision engineering in every overhead lifting solution we deliver. Our bridge cranes are meticulously designed, manufactured from

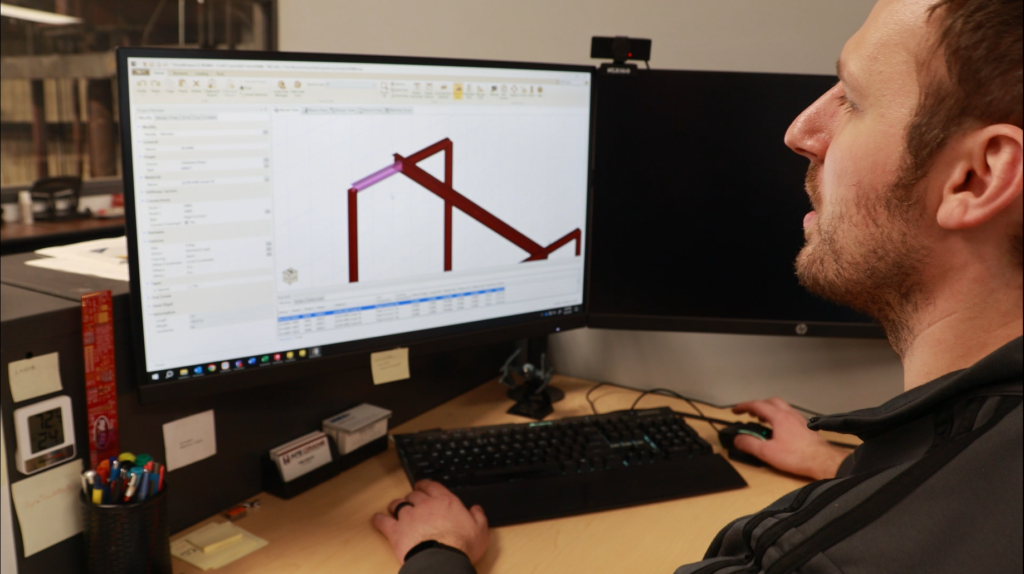

Support steel refers to the structural framework that holds up the crane runway beams. It includes columns, headers, and bracing that ensure the runway system can handle the loads imposed by the crane and its operations.

Support steel is designed based on the crane’s capacity, runway span, and expected loading conditions. Engineers calculate deflection limits, lateral forces, and column reactions to ensure the structure meets industry standards and safety requirements.

Yes, AFE Crane provides turnkey support steel installation for overhead crane runways. We coordinate with professional engineers to analyze your existing building and determine if modifications or reinforcements are needed. Our team then fabricates the support steel at our Cedar Falls, Iowa facility and completes the installation, ensuring seamless integration with your crane system.

PO Box 487

1824 Lincoln Street

Cedar Falls, IA 50613

"*" indicates required fields

By subscribing you agree to with our Terms & Conditions and provide consent to receive updates from our company.