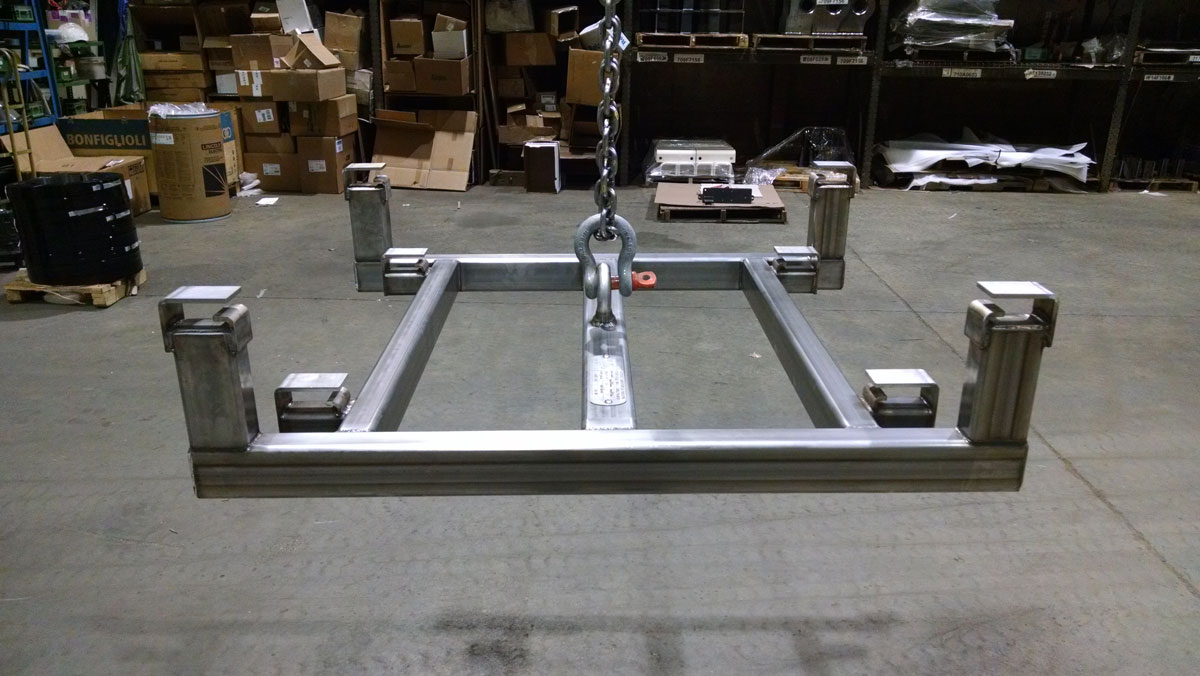

4 Ton Side Shifting Load Bar

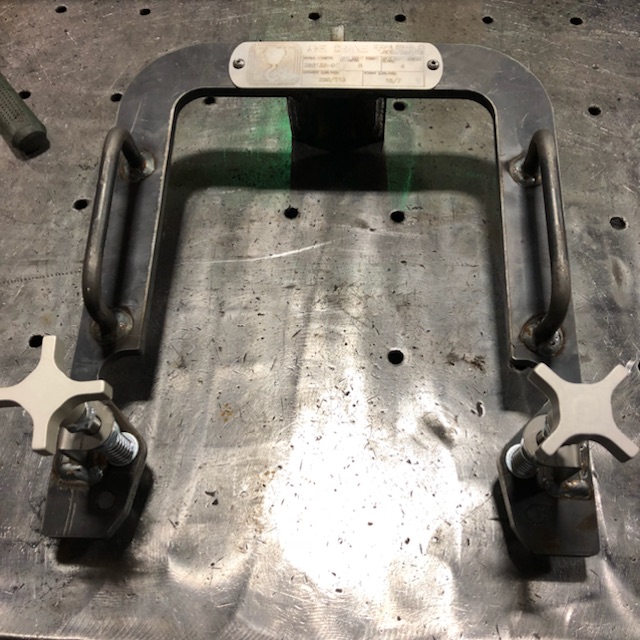

Below Hook Lifting Device with Anti-Scratch Protection

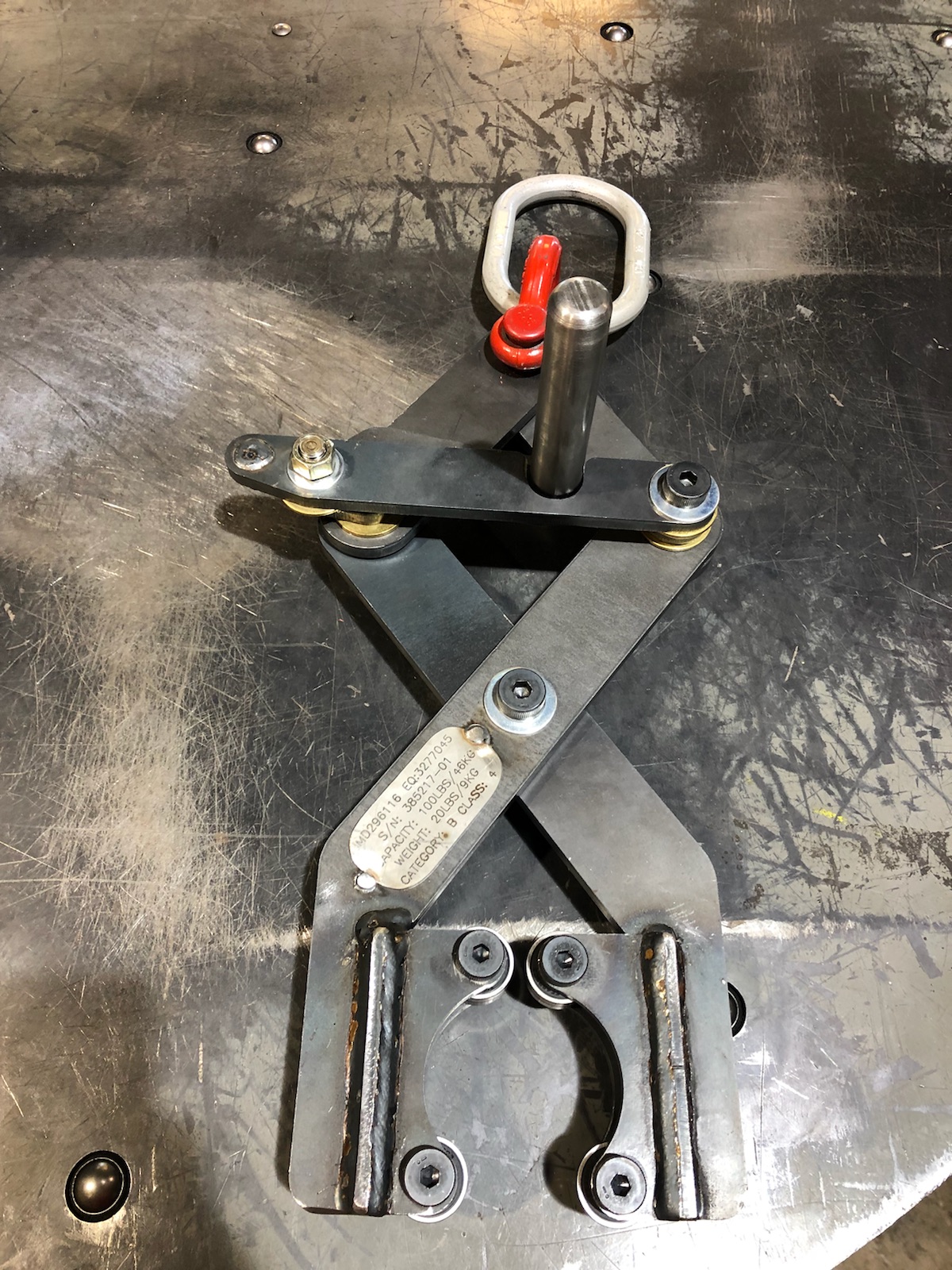

Below-the-Hook Lifting Device

Below-the-Hook Lifting Device

Below-the-Hook Lifting Device

Below-the-Hook Lifting Device

Below-the-Hook Lifting Device

Below-the-Hook Lifting Device

Below-the-Hook Lifting Device

4000 lbs Capacity, 180 ft Long Below-the-Hook Lifting Device

Below-the-Hook Lifting Device

Below-the-Hook Lifting Device

Vacuum Sheet Lifter

Below-the-Hook Lifting Device

Below-the-Hook Lifting Device

4000 lbs Capacity, 180 ft Long Load Bar