Understanding Upper Limit Switches in Wire Rope Hoists

Upper limit switches are a critical safety component in any wire rope hoist system. These devices are engineered to stop the upward motion of the hook block and prevent “two-blocking”—a dangerous scenario where the hook block strikes the drum. Without a reliable upper limit switch, the result can be catastrophic: wire rope failure, equipment damage, or even a dropped load.

Why Upper Limit Switches Are Critical

Why Upper Limit Switches Are Critical

When a hoist lacks a properly functioning upper limit switch, it risks driving the hook block into the hoist drum. This can lead to severe damage to the mechanical system and the wire rope, introducing the potential for sudden equipment failure. These hazards demonstrate why it’s essential to install and maintain hoists that meet strict safety standards, like ASME B30.16.

🔗 Learn more about ASME B30.16 standards at asme.org

Comparing U.S. and European Hoist Standards

U.S. Hoist Safety Standards

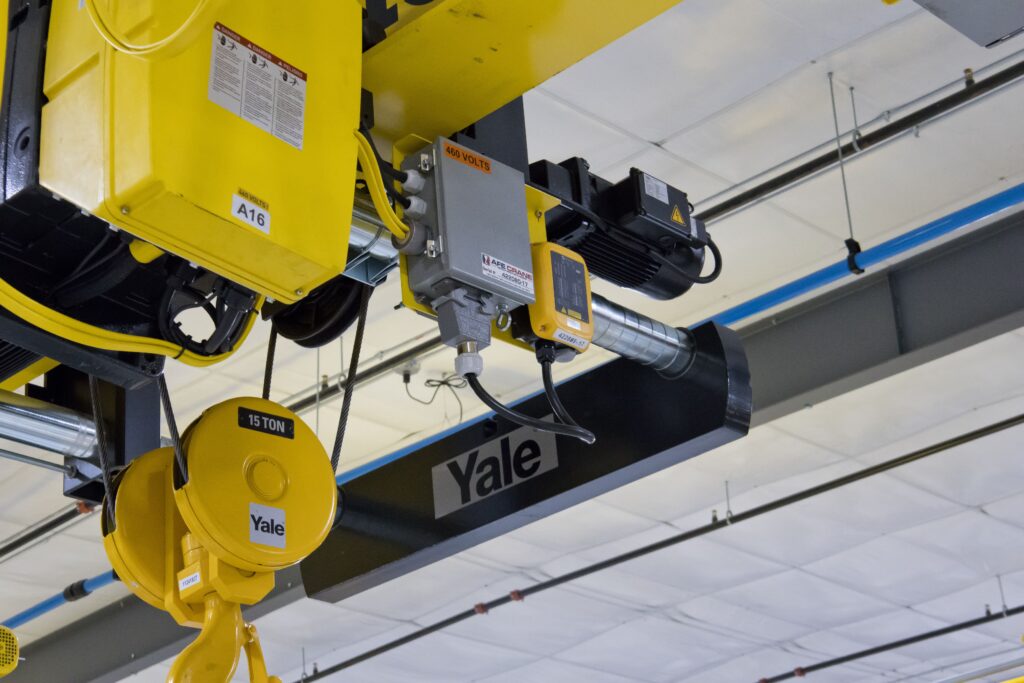

Hoists manufactured in the U.S. generally follow ASME B30.16, which requires an independent safety mechanism to prevent upward overtravel. American hoists often include a weight- or lever-operated upper limit switch by default. For enhanced safety, some systems also integrate a geared limit switch.

Brands that follow this standard include:

-

Acco

-

Detroit Hoist

-

Yale Shawbox

-

ElectroLift

-

Saturn

European Safety Approach

In contrast, European hoist manufacturers typically rely on a geared limit switch as the primary control for upward travel. While effective, this singular method lacks redundancy. Brands such as Demag, Harrington, Street, Stahl, and R&M use this approach, which represents a different design philosophy—one that can lead to safety gaps if not supplemented.

Real-World Example: The Case for Redundancy

At AFE Crane, we witnessed a near-miss that reinforced our safety-first mindset. A hoist built to European specifications suffered a geared limit switch failure. Fortunately, a vigilant operator stopped the lift manually before it caused damage.

This situation confirmed our position: a redundant limit switch system is best. That means pairing an ASME B30.16-compliant hoist with a secondary geared limit switch for added protection and peace of mind.

How to Choose a Safe Wire Rope Hoist

When selecting a hoist, prioritize systems with both mechanical and geared upper limit switches. This layered approach ensures:

-

Compliance with ASME B30.16

-

Reduced risk of catastrophic equipment failure

-

Extended equipment life

-

Safer working environments

Explore our custom engineered crane solutions to find a setup that meets your specific safety requirements.

Final Thoughts

Upper limit switches are more than a feature—they’re a necessity. Companies that take the time to evaluate their hoist equipment and safety compliance can prevent accidents, reduce downtime, and protect valuable assets. At AFE Crane, we prioritize reliability, performance, and operator safety in every solution we provide.