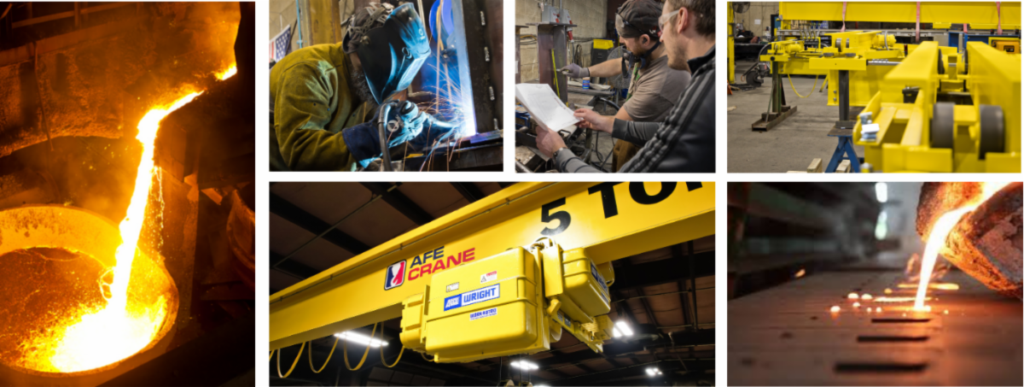

Heavy-Duty Cranes Engineered for Hot Metal HandlingAt AFE Crane, we specialize in designing and manufacturing heavy-duty crane systems built to withstand the extreme conditions of steel mills, foundries, and metal processing facilities. Our expertly engineered solutions ensure safe and efficient material handling, even in the most demanding environments.

Handling molten metal requires specialized equipment that prioritizes durability, high heat resistance, and enhanced safety measures. Our specialty cranes are designed not only to withstand extreme temperatures but also to meet the highest industry safety standards.

Built to Last

AFE Crane adheres to strict industry regulations to ensure the longevity and reliability of our systems. Our designs comply with:

- ASTM E2349, 2019 (superseding ANSI Z541.2), outlining best practices for foundry equipment.

- NFPA 70: National Electric Code, 2023, ensuring all electrical components meet modern safety and performance standards.

By following these rigorous industry standards, we deliver cranes that provide long-term reliability and performance, even in high-heat, heavy-load environments.

Key Features for Reliability

AFE Crane’s molten metal handling cranes incorporate several high-performance features designed to maintain continuous operation in extreme environments:

- Class H motor insulation to endure intense heat and prolonged use.

- High-temperature oil and grease to maintain proper lubrication and prevent premature wear.

- NEMA 4/12 steel enclosures to protect electrical components from dust, debris, and moisture.

- Heat shields that effectively deflect direct heat, ensuring essential components stay cool and functional.

These features reduce downtime, improve performance, and extend the lifespan of your crane system.

Safety Enhancements

Safety is paramount when dealing with molten metal lifting and transportation. Our cranes integrate multiple redundant safety measures to ensure worker protection and prevent catastrophic failures:

- Secondary mechanical braking to provide an added layer of stopping power.

- 8:1 wire rope safety factor, exceeding standard lifting safety requirements.

- Special overload protection to prevent excessive stress on hoisting components.

- Drop lugs and safety cables for additional protection against accidental drops.

- Visual and auditory warning systems to alert operators of crane movements, improving workplace awareness.

By integrating these safety measures, AFE Crane minimizes risks and enhances operational security, making our cranes a trusted choice for high-risk environments.

Designed to Meet Your Demands

Every foundry and steel mill has unique requirements. That’s why AFE Crane offers custom-engineered solutions tailored to your specific lifting needs. Whether you require higher weight capacities, extreme heat resistance, or specialized motion controls, our team of Application Engineers is here to help.

Explore our full range of heavy-duty crane systems on our website and contact our team today to discuss the best lifting solution for your molten metal handling operations.