Understanding the Risks of Hoist Side Pull

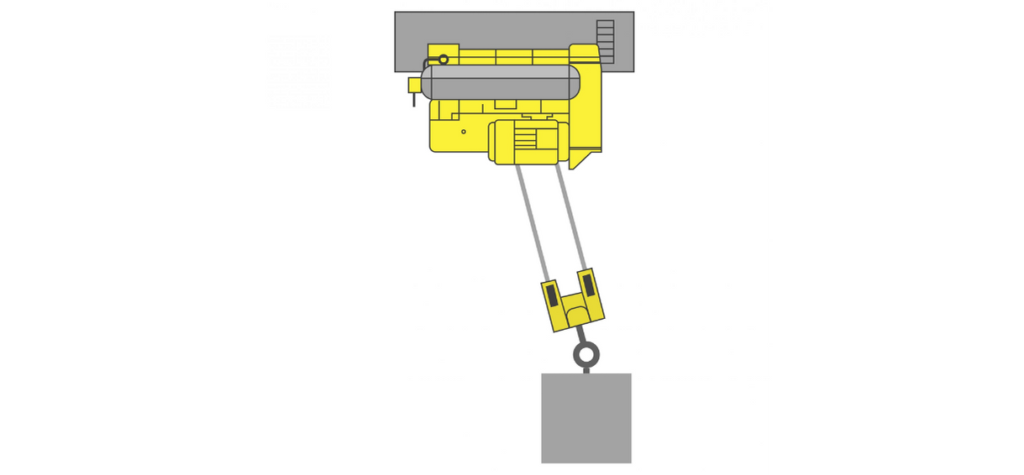

Overhead cranes play a crucial role in industrial operations, lifting and transporting heavy loads with precision. However, improper usage can introduce serious safety hazards. One of the most common and dangerous mistakes in crane operation is side pulling, which occurs when the center of gravity of a load is not positioned directly beneath the hoist.

Side pulling can lead to several issues, including:

- Damage to the hoist: Hoists are designed to lift loads vertically, and lateral forces can cause premature wear, misalignment, or even catastrophic failure.

- Injury to personnel: A side pull can cause an unstable lift, leading to dropped loads or unexpected movements that put workers at risk.

- Damage to nearby equipment and structures: An uncontrolled swing or movement of the load can strike surrounding machinery, structures, or other materials, leading to costly repairs and downtime.

The Role of Tilt Sensors in Side Pull Detection

To prevent side pulling and enhance hoist safety, equipping a hoist with advanced tilt sensor technology provides an extra layer of accident prevention. Laser-View Technologies’ DIS Tilt Sensor is an innovative solution that detects potential side pull conditions in real time and integrates with hoist controls to prevent unsafe lifts.

This two-axis MEMS-based tilt sensor is mounted on a plate and clamped to the dead end of the wire rope near the hoist frame. By continuously monitoring the wire rope’s angle, the sensor can detect any deviation from a true vertical lift. If a side pull is detected, the system can immediately trigger a response, such as disabling the hoist or providing an alert to the operator.

Benefits of Implementing Side Pull Detection

Using a tilt sensor system for side pull detection brings several operational and safety advantages:

- Improved Equipment Longevity – Prevents premature wear and damage to the hoist, wire rope, and associated lifting components.

- Enhanced Workplace Safety – Reduces the risk of dropped loads, unexpected movements, and worker injuries.

- Compliance with Safety Standards – Helps businesses adhere to OSHA regulations and industry best practices for crane operation.

- Minimized Downtime and Repairs – Prevents costly accidents and ensures continued production efficiency.

Integrating Tilt Sensors with Hoist Controls

One of the key advantages of Laser-View Technologies’ hoist side pull detection system is its ability to seamlessly integrate with existing hoist controls and safety mechanisms. When a potential side pull is detected, the system can be configured to:

- Trigger an alarm to warn the operator.

- Disable the hoist lift function until the condition is corrected.

- Send diagnostic data for further analysis and preventive maintenance.

By leveraging this smart detection technology, crane operators can proactively prevent unsafe lifting conditions before they escalate into costly or dangerous incidents.

Conclusion

Side pulling remains a significant concern in hoist operation, but with the right safety technology in place, these risks can be minimized. Implementing tilt sensor-based side pull detection ensures a safer working environment, extends the lifespan of crane components, and helps maintain compliance with industry safety standards.

For more information on Hoist Side Pull Detection, visit Laser-View’s website and contact your AFE Crane representative today!