Overview

AFE Crane partnered with a local manufacturing customer located just one mile north of their manufacturing facility in Cedar Falls, Iowa, to address a specific material handling challenge within their paint booth operations. The customer required a customized solution that could enhance efficiency and safety in a confined space, while meeting the strict safety standards required for a paint booth environment.

Project Challenge

The project involved several key challenges. The workstation crane had to be designed to fit within the tight dimensions of the customer’s paint booth without compromising lifting capabilities. Maximizing headroom in the limited vertical space was critical, as the equipment needed to accommodate large and heavy parts. Additionally, the paint booth application necessitated the use of spark-resistant materials to ensure safety in a high-risk environment. Finally, the crane system had to support a 2-ton air hoist capable of handling the customer’s heavy components, all while integrating seamlessly into their existing operations.

The AFE Crane Solution

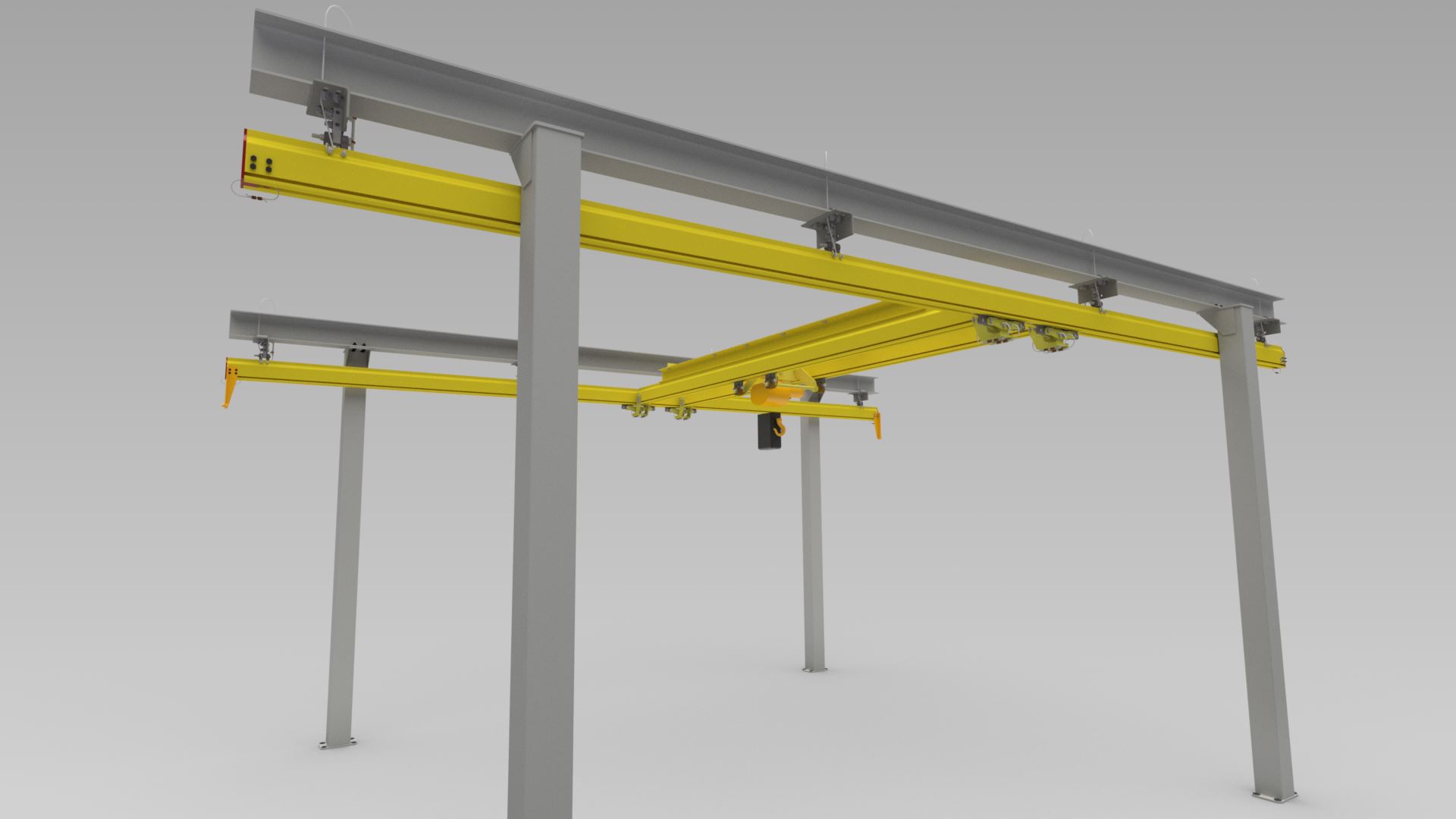

AFE Crane developed a custom freestanding workstation crane system to meet the customer’s unique requirements. The design utilized Unified’s workstation rail for both the runway and bridge to create a lightweight yet durable structure that ensured smooth operation. To address the space constraints, the crane featured a double girder bridge equipped with low headroom end trucks and a low headroom hoist carrier. This innovative design allowed the hoist to be positioned within the double girders, maximizing the available vertical space in the booth. Recognizing the safety requirements of the paint booth application, AFE Crane selected materials and components that adhered to strict spark-resistant standards. The system was equipped with a 2-ton CM Budgit air hoist, which enabled the safe and efficient lifting of heavy parts in and out of the paint booth. AFE Crane provided a complete turnkey solution, beginning with concept consultation and custom system design by our Applications and Product Engineers. The process included local fabrication, on-site installation, system start-up, and load testing to guarantee a smooth and efficient implementation.

Project Execution

The custom workstation crane system delivered significant improvements to the customer’s paint booth operations. By optimizing the limited vertical clearance with a low headroom design, the system allowed the customer to make full use of their confined space. The inclusion of spark-resistant materials ensured a safe working environment, mitigating potential risks in the paint booth. With the robust 2-ton air hoist, the customer was able to handle their heavy components efficiently, reducing manual handling time and effort. AFE Crane’s turnkey approach minimized downtime during installation, enabling the system to become operational quickly and seamlessly.

Conclusion

This project exemplifies AFE Crane’s ability to deliver innovative, customer-focused solutions tailored to specific operational challenges. By addressing space constraints, safety considerations, and heavy-duty lifting requirements, AFE Crane provided a custom workstation crane system that enhanced both safety and efficiency. This case demonstrates AFE Crane’s commitment to engineering excellence and customer satisfaction. For more information about custom material handling solutions, contact AFE Crane today.