Call us today at (800) 728-0818

AFE Crane understands that when your crane goes down, your production may come to a standstill. Cranes are complex pieces of equipment that repetitively move and lift heavy loads which can result in the need for repair. Our services experts are experienced and knowledgeable about overhead cranes as well as all the systems supporting them. Our goal is to accurately diagnose a repair solution and get your equipment back up in working order as soon as possible.

Being a crane manufacturer, we can also provide a recommended preventative maintenance program tailored to your particular application usage. Years of experience have taught us that if you make scheduled inspections you can catch problems early on, before they become a bigger problem, like shutting down your operation.

Choosing a reliable company to maintain your overhead crane is crucial for safety, efficiency, and cost savings. Here are some points to consider and how we approach them at AFE Crane.

Industry Experience: Look for a company with a proven track record in overhead crane maintenance. AFE Crane has been manufacturing and repairing overhead cranes and hoists since 1983.

Service Offerings:

Choose a company that offers custom maintenance plans that inspect the crane and address your needs and situation. Ask the company about their inspection procedures. See AFE Crane’s inspection procedures.

Our trained service technicians have the skills and experience to repair a wide range of crane components, including electrical systems, brakes, and rigging.

Look for a company that offers customized preventive maintenance programs. At AFE Crane we customize a program to your specific crane and usage and demands and determine the best frequency of inspections to keep your crane system in working order and to help reduce downtime.

We communicate clearly with our customers and keep them informed about their crane’s condition and any recommended maintenance actions.

OSHA requires that all overhead cranes must be inspected on an annual basis, but is that good enough? Maintenance and inspections should be based on usage, age of the equipment, and the type of applications your crane encounters. Once that is identified we can create a regularly scheduled maintenance program tailored to meet your usage needs.

Regular maintenance is important for ensuring the safe operation of your crane. A malfunctioning crane can lead to serious accidents and injuries. Our visual inspection and testing can catch minor issues early through maintenance can prevent them from turning into major repairs that shut down your operation and cost a significant amount. A custom maintenance schedule can extend the life of your crane by catching small issues before they become big and costly ones.

Inspect for chain or wire rope wear, elongations of the chain links, broken wire rope strands, proper lubrication, and functionality of limit switches.

Check for cracks, deformations, and ensure the latch functions properly.

Check for misalignment, cracks, and wheel wear, and inspect the runway and bridge beam tread for wear or damage, ensuring they are smooth and free from deformities that could affect the crane’s operation.

Inspect for smooth movement, proper lubrication, and functionality of brakes.

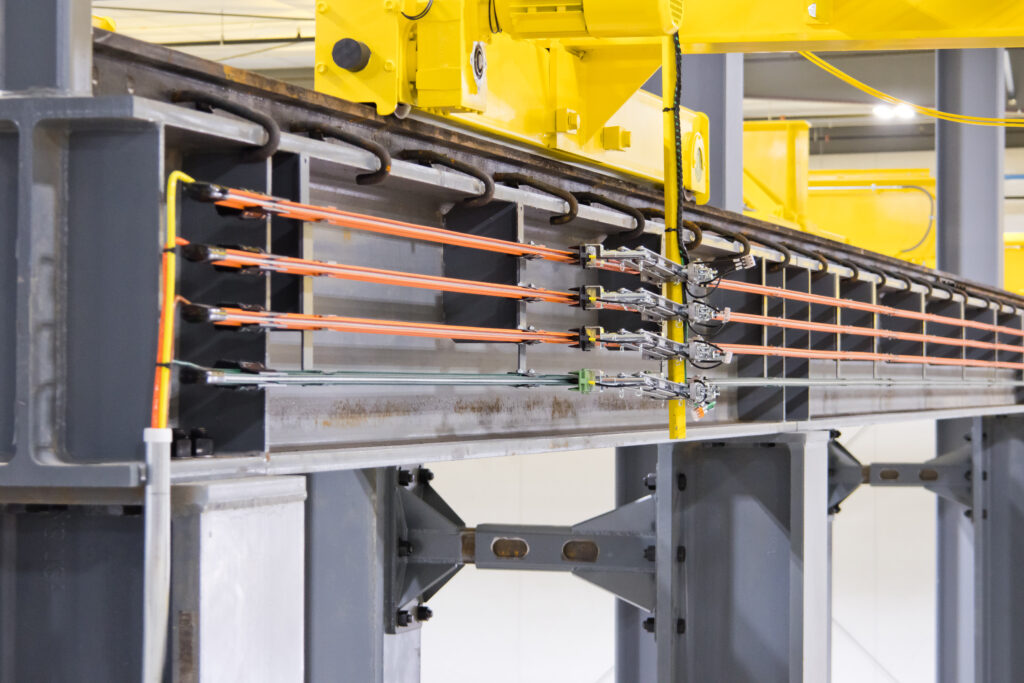

Ensure proper connections, no exposed wiring, and functionality of controls and emergency stop.

As with any complex machinery, overhead cranes are susceptible to wear and tear over time. There is an infinite number of repair items for cranes, but we have compiled a breakdown of some of the most common repairs needed for overhead cranes.

The wire rope is a critical component that lifts and lowers loads. Constant use can lead to fraying, broken strands, or corrosion. These signs indicate the need to replace the entire wire rope to prevent a potential failure that could drop a load.

The hoist brakes ensure safe and controlled lowering of loads. Friction from stopping heavy loads can wear down the brake pads over time. Symptoms of failing brakes include jerky lowering or an inability to hold a load securely. Worn brake pads need to be replaced to maintain safe operation.

The end trucks & hoist trolley contain the wheels that travel along the runway or bridge beam. These wheels can wear unevenly or become chipped due to misalignment, overloading, or simply normal wear and tear. Unevenly worn wheels can cause the crane or hoist to skew or bind on the track, requiring replacement to ensure smooth operation.

Overhead cranes rely on complex electrical systems for power and control. Loose connections, faulty contactors, or malfunctioning limit switches can all lead to electrical problems. A qualified technician will diagnose the issue and repair or replace the necessary electrical components.

The hook is a vital component that bears the brunt of the lifting force and can develop cracks, deformations, or damage over time from heavy loads or improper use. Repairs to the safety latch may be needed, or in severe cases, the hook may require replacement to prevent failure. We can also upgrade your hook to a style better suited to your manufacturing setting, such as a Bullard or Shur Loc hook, enhancing both safety and functionality.

These are just a few examples, and the specific repairs needed will vary depending on the age, usage, and maintenance history of your crane. Regular inspections and preventive maintenance can help identify and address these issues before they become major repairs.

At AFE Crane, we prioritize reliability, durability, and precision engineering in every overhead lifting solution we deliver. Our bridge cranes are meticulously designed, manufactured from

At AFE Crane, we understand that proper training and ongoing support are crucial for the safe and efficient operation of your crane systems. A well-trained