In the realm of material handling, the advent of foundationless jib cranes marks a significant shift from traditional systems. Unlike conventional jib cranes that necessitate dedicated concrete footings to counteract operational loads, foundationless jib cranes are ingeniously designed to be mounted directly onto existing reinforced concrete floors. This innovation simplifies installation and offers unparalleled flexibility in workspace configuration.

Advantages of Foundationless Jib Cranes

-

Cost Efficiency: Eliminating specialized concrete foundations results in substantial cost savings. Traditional foundations can often match or exceed the cost of the crane itself, making foundationless options a more economical choice.

-

Swift Installation: Without the requirement for concrete curing—a process that can extend over a week—foundationless jib cranes can be installed and operational in a fraction of the time, minimizing downtime and enhancing productivity.

-

Enhanced Mobility: The ability to relocate these cranes with relative ease allows facilities to adapt to evolving operational needs without the constraints imposed by fixed foundations. This mobility ensures optimal utilization of workspace and resources.

-

Space Optimization: By mounting directly onto existing floors, foundationless jib cranes free up valuable floor space that would otherwise be occupied by large foundations, thereby optimizing the available working area.

Spanco’s 605 Series Foundationless Workstation Jib Cranes

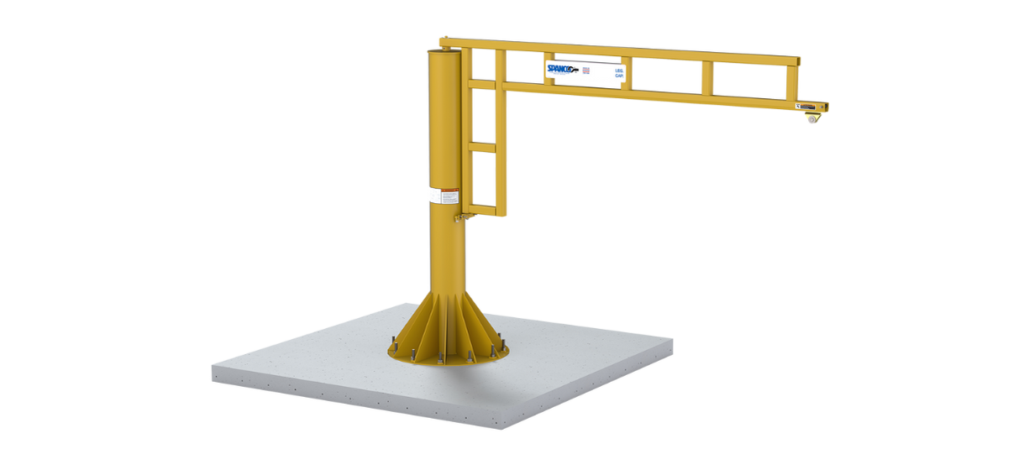

A notable example in this category is Spanco’s 605 Series Foundationless Workstation Jib Crane. Key specifications include:

- Capacity: Up to 1,000 lbs

- Span: 4 to 16 feet

- Height Under Boom: 8 to 16 feet

- Boom Rotation: 360 degrees

These cranes are engineered to be bolted onto reinforced concrete floors without the need for additional foundations, provided the floor meets specific structural criteria. This design facilitates quick installation and the flexibility to relocate the crane as operational demands evolve.

Considerations for Implementation

While foundationless jib cranes offer numerous benefits, certain conditions must be met to ensure safe and effective operation:

-

Floor Requirements: A minimum of six-inch-thick, 3,000 PSI reinforced concrete is necessary to securely anchor the crane.

-

Load Limitations: These cranes are typically suited for lighter loads, with capacities generally up to 1,000 lbs, making them ideal for tasks that do not require heavy lifting.

-

Operational Scope: Foundationless jib cranes are optimal for applications requiring localized material handling within a defined area, such as individual workstations or specific segments of a production line.

Conclusion

Foundationless jib cranes represent a strategic advancement in material handling solutions, offering cost savings, installation efficiency, and operational flexibility. By eliminating the need for dedicated foundations, these cranes empower facilities to adapt swiftly to changing workflows and spatial configurations, thereby enhancing overall productivity. For organizations seeking versatile and efficient lifting solutions, foundationless jib cranes present a compelling option worthy of consideration.

If you’re looking for a jib crane solution, give us a call, and we will work with you to select a design that best meets your needs.