Ensuring the safety of workers operating at heights is a critical responsibility in various industries. Implementing effective fall protection measures not only safeguards employees but also ensures compliance with regulatory standards. Understanding when fall protection is required and the types available is essential for creating a safe working environment.

When Is Fall Protection Required?

OSHA mandates fall protection based on specific elevation thresholds across different industries:

- 4 feet – Required for general industry workplaces.

- 5 feet – Required for shipyards.

- 6 feet – Required for construction industry work.

- 8 feet – Required for longshoring operations.

Additionally, OSHA requires fall protection when working over dangerous equipment and machinery, regardless of the fall distance.

Types of Fall Protection

Fall protection strategies can be categorized into several types, each serving a specific purpose in preventing or arresting falls:

- Hazard Elimination: The most effective method, this involves modifying the work environment or procedures to remove the need to work at height. For example, using extendable tools to perform tasks from ground level.

- Passive Fall Protection: This includes physical barriers such as guardrails or parapets that prevent workers from reaching fall hazards. These systems require minimal training and are considered passive because they do not rely on active participation from the worker.

- Fall Restraint Systems: These systems prevent workers from reaching areas where they could fall. They typically involve a full-body harness and a lanyard connected to an anchor point, restricting the worker’s movement to safe areas. Authorized person training and a written rescue plan are required for these systems.

- Fall Arrest Systems: Designed to stop a fall in progress, these systems consist of a personal fall arrest system (PFAS) or protective netting. A PFAS includes an anchorage, body wear (full-body harness), and connecting devices such as shock-absorbing lanyards or self-retracting lifelines. These systems require authorized person training and a written rescue plan.

- Administrative Controls: These are the least preferred and effective methods, used when conventional fall protection is not feasible. They involve implementing work practices or procedures to minimize the risk of falls, such as warning signs or restricted access areas. A written rescue plan is required when using administrative controls.

Why Choose Rigid Lifelines for Fall Protection?

When it comes to fall protection, choosing the right system is crucial for ensuring both compliance and worker safety. Rigid Lifelines specializes in innovative, high-quality fall protection solutions designed to provide superior safety and ease of use. Their product lineup includes:

- Rigid Rail Systems: Unlike traditional cable-based systems, rigid rail fall arrest systems minimize fall distances, reducing the risk of secondary injuries from sudden stops. These systems are ideal for applications in manufacturing, warehousing, and maintenance settings.

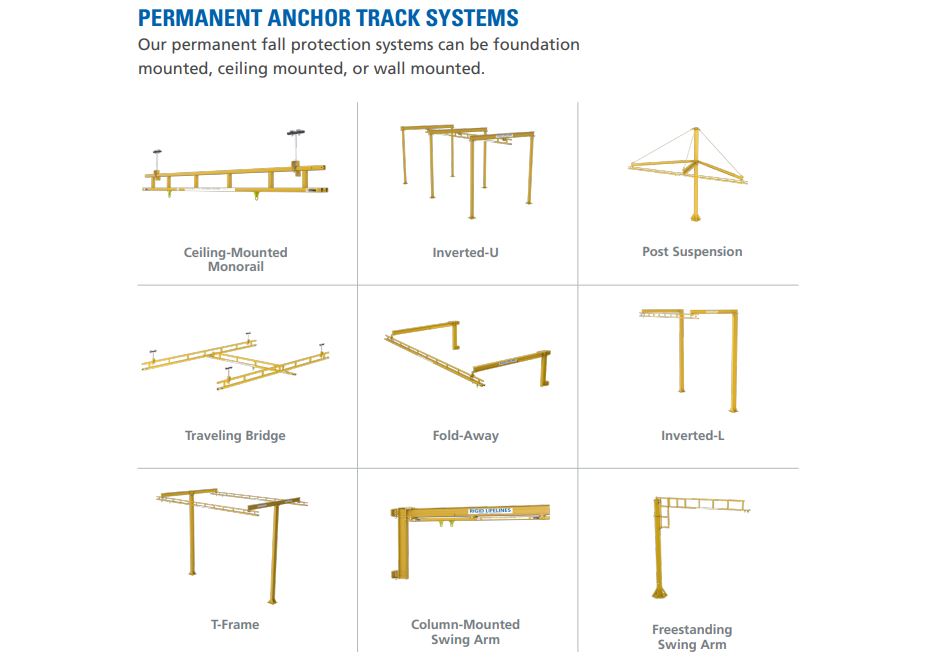

- Overhead Track Systems: Providing continuous coverage for workers operating at heights, overhead track systems offer smooth, uninterrupted movement along the work area, ensuring optimal safety and productivity.

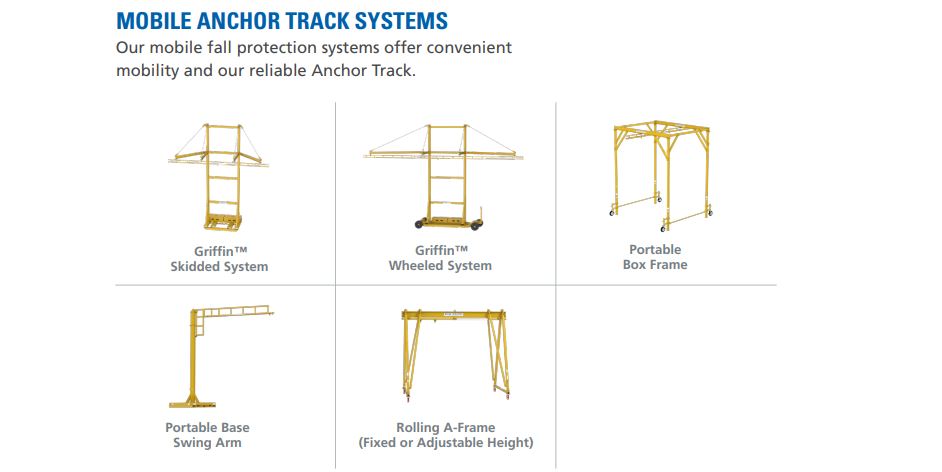

- Portable Fall Protection Systems: For applications where permanent solutions aren’t feasible, Rigid Lifelines offers mobile systems that provide reliable fall protection across multiple worksites.

- Self-Retracting Lifelines (SRLs): Designed for ease of movement and automatic fall arrest, SRLs provide an added layer of protection by locking immediately upon detecting a fall.

- Custom Solutions: Rigid Lifelines understands that every worksite is unique. Their engineering team works closely with businesses to design custom fall protection solutions tailored to specific applications and environments.

Investing in Worker Safety

Understanding when fall protection is required and the various types available is crucial for maintaining a safe work environment. Employers must assess their workplaces, identify potential fall hazards, and implement appropriate measures to protect their workers. By adhering to OSHA guidelines and utilizing effective fall protection systems, organizations can significantly reduce the risk of fall-related injuries and fatalities.

Choosing Rigid Lifelines means investing in durable, OSHA-compliant fall protection solutions that reduce risks and enhance workplace safety. With advanced engineering, superior quality, and a commitment to innovation, Rigid Lifelines is the trusted partner for businesses looking to protect their employees working at heights.

For more information on their fall protection systems and how they can enhance safety in your facility, visit Rigid Lifelines today.