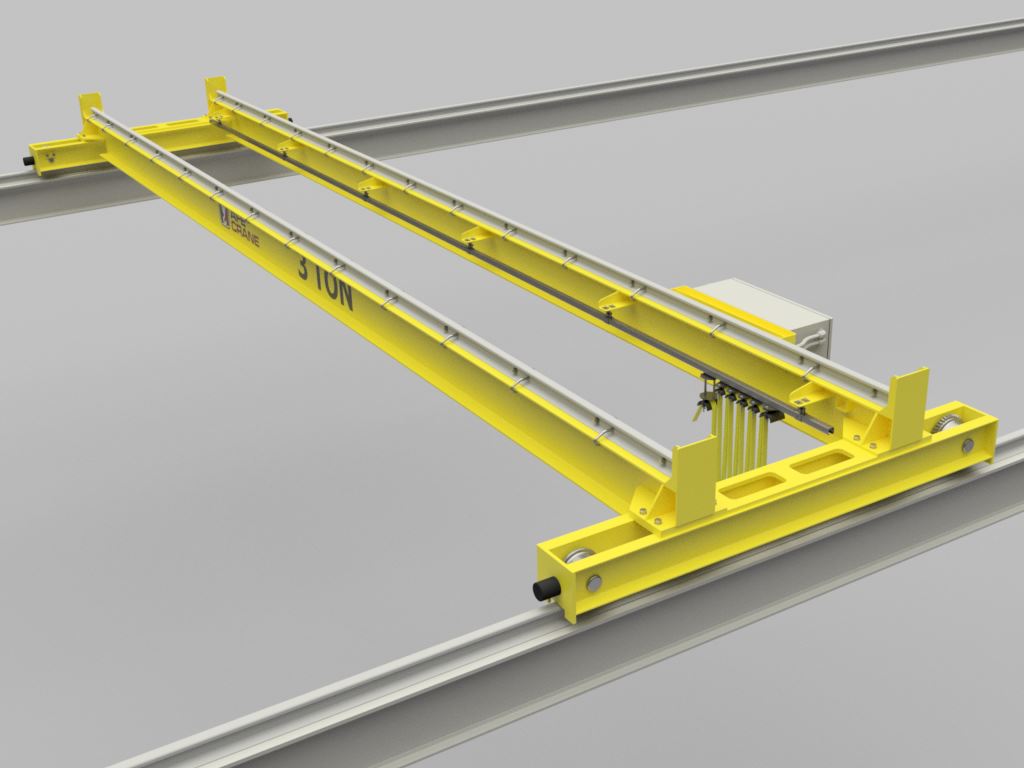

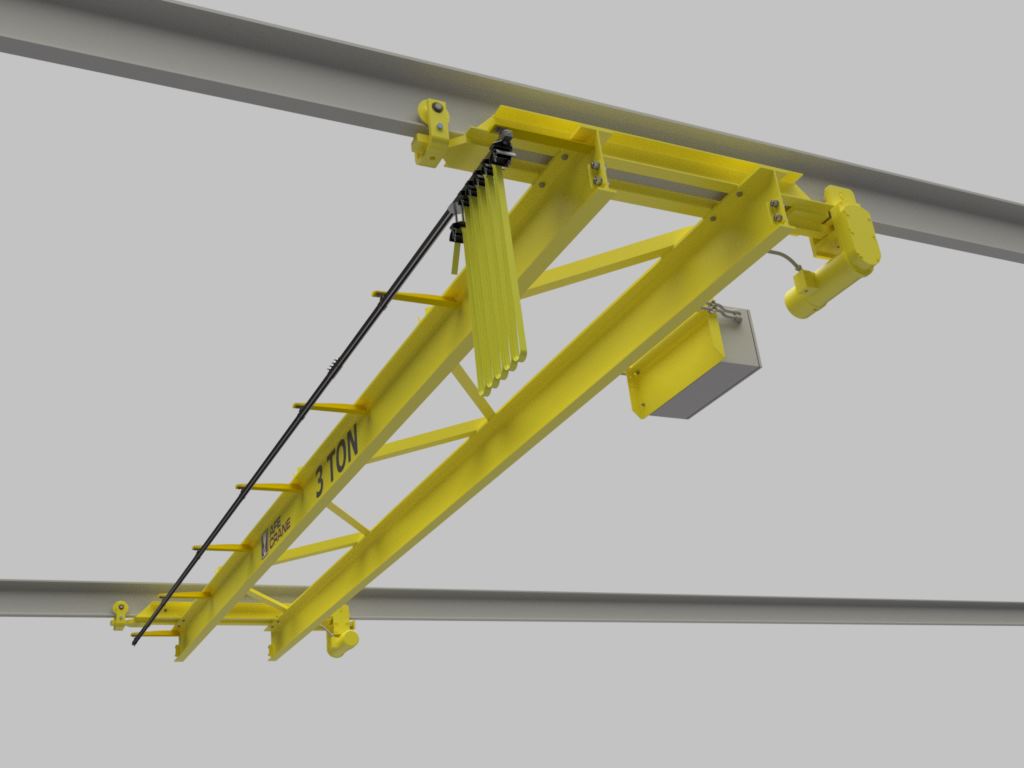

A Top Running Single Girder (TRSG) bridge crane is the most common type of overhead bridge crane. It is a versatile bridge crane that can be utilized for a wide variety of industries. TRSG cranes can be built with capacities up to 15 ton and spans up to 98 ft. Typically, TRSG crane capacities vary between 5 and 10 ton. With these capacities, the bridge beam is typically a wide flange structural member. Most cranes that exceed a capacity of 10 ton with a span greater than 60 ft will utilize a box girder bridge beam.

The hoist/trolley used on a TRSG crane is always an under hung style trolley which runs on the bottom flange of the bridge beam. For this reason, a TRSG crane is not the best crane option if facility headroom is a major issue. See Top Running Double Girder cranes if headroom is a key factor.