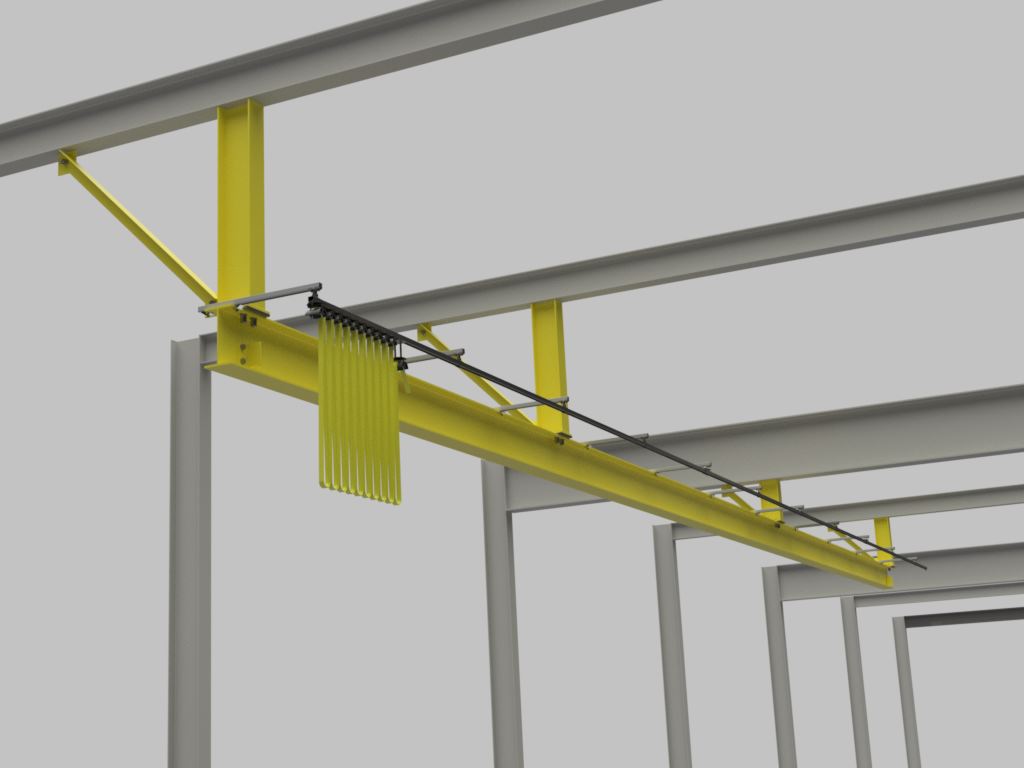

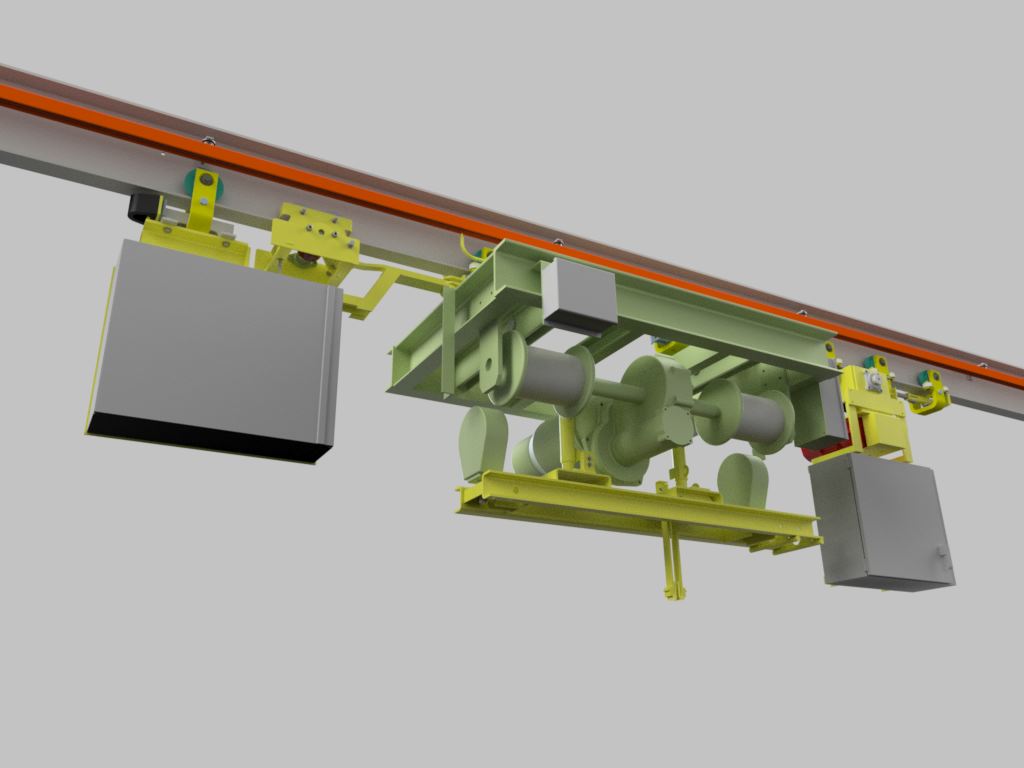

Monorail systems move materials and parts in a fixed path using a single rail. An overhead monorail systems is an excellent solution when moving parts from station-to-station in an assembly facility, when storing/queueing parts overhead to save floor space, or staging parts in a paint booth or similar. When using a simple or straight monorail path, the system can easily be mounted using a freestanding frame system or directly hung from the existing building structure (as long as the building design allows). Complex systems can be hung using the same methods but may take additional structural steel to support the additional track devices i.e. tongue switches, sliding switches & interlocking latches. Using enclosed track or patented track would be best for a complex monorail system. AFE Crane prefers using Acco Louden patented track, due to there vast variety of components for monorail systems. AFE Crane is able to increase safety & productivity by designing a monorail system that suits your needs.